Flip Chip Machines for Assembly of Facing Down Chips/Dies

Our laser assisted bonding machines for flip chip offers a range of benefits that address common challenges in interconnection processes. With our technology, we can effectively address the issue of thermal stress caused by long reflow time, which can negatively impact the reliability and performance of the device. By using our machines, we can depress thermal stress and ensure that the components surrounding the bonding area are not affected by excessive heat. This is crucial in maintaining the integrity of the device and preventing any potential damage or malfunctions.

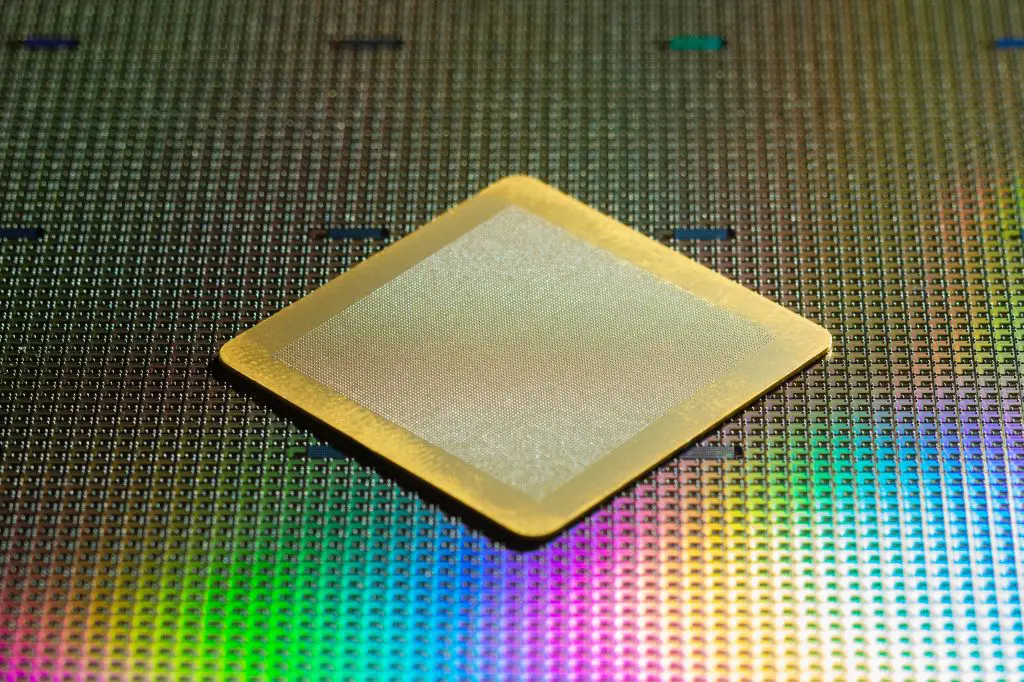

While our laser assisted bonding machines focuses on mitigating thermal stress, it’s important to note that flip chip bonding itself provides a range of advantages over other interconnection processes. One significant advantage is the ability to achieve a higher input/output (I/O) count. Unlike other processes, flip chip bonding utilizes the entire area of the die for connections. This means that more connections can be made, resulting in increased functionality and improved performance of the device.

In addition to the higher I/O count, flip chip bonding also offers improved speed compared to wire bonds. By utilizing shorter interconnection paths, the signal transmission within the device is optimized. This leads to enhanced speed and overall device efficiency. The reduced distance that signals need to travel contributes to faster operation and improved response times.

Furthermore, flip chip bonding provides a smaller form factor compared to wire bonding. By eliminating the need for wire bond loops, the overall size of the device can be reduced significantly. This allows for more compact designs and enables the integration of more components within a limited space.

In conclusion, our laser assisted bonding machines for flip chip addresses the specific challenge of thermal stress and heat effects in interconnection processes. However, it’s important to recognize that flip chip bonding as a whole offers a range of advantages including a higher I/O count, improved speed, and a smaller form factor. These benefits collectively contribute to enhancing the performance, functionality, and compactness of electronic devices.

Flip Chip Equipment

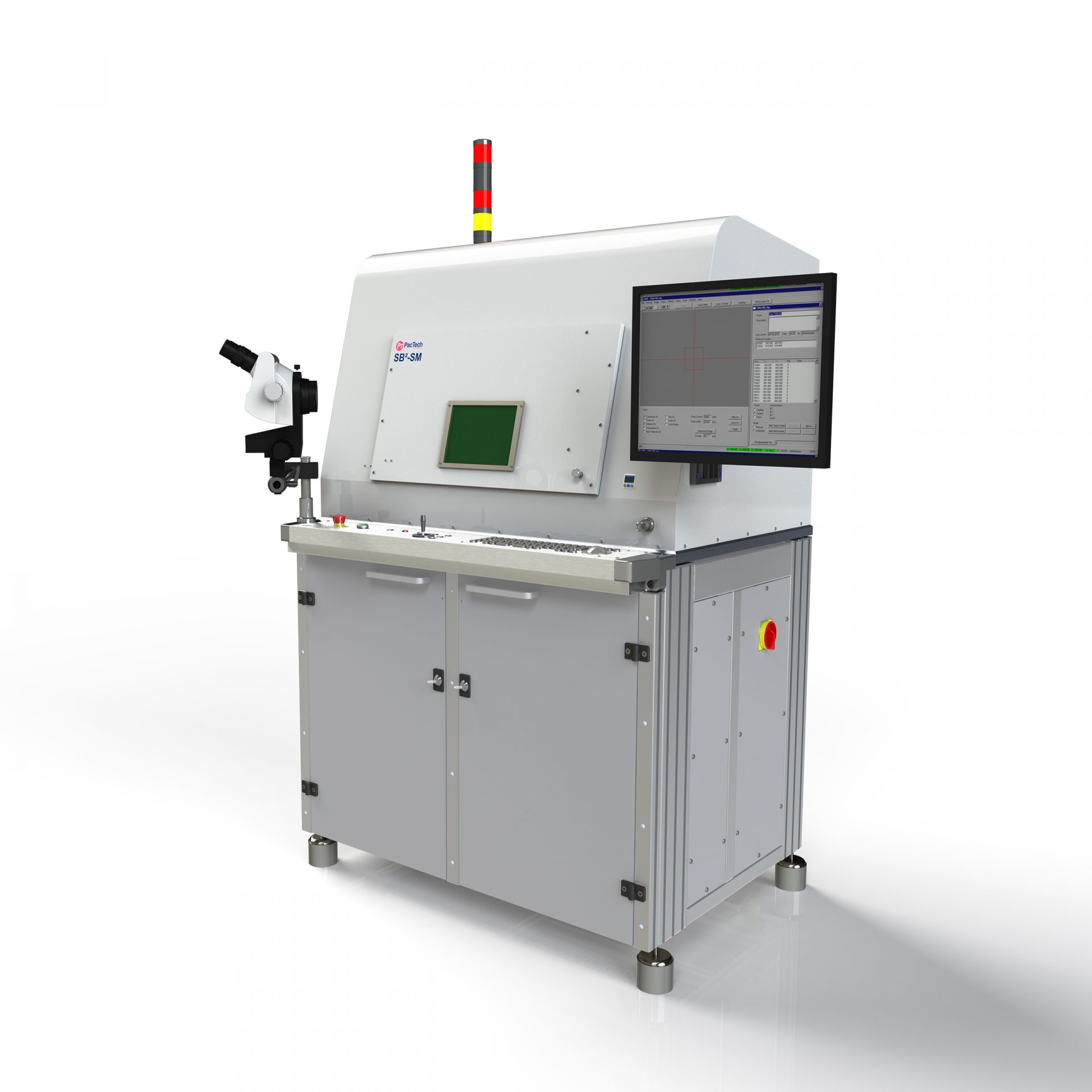

SB² – SM

The SB2-SM is a machine for prototyping and small volume production that has wider working area than the SB2-M and more optional features.

SB² – Compact

SB²-Compact machine is the SB² entry point for high volume production with highly flexible and ultra-compact workstation.

Ultra – SB²

Ultra-SB2 is a fully automated solder bumping equipment integrating flux printing, ball placement, 2D inspection and wafer level rework.

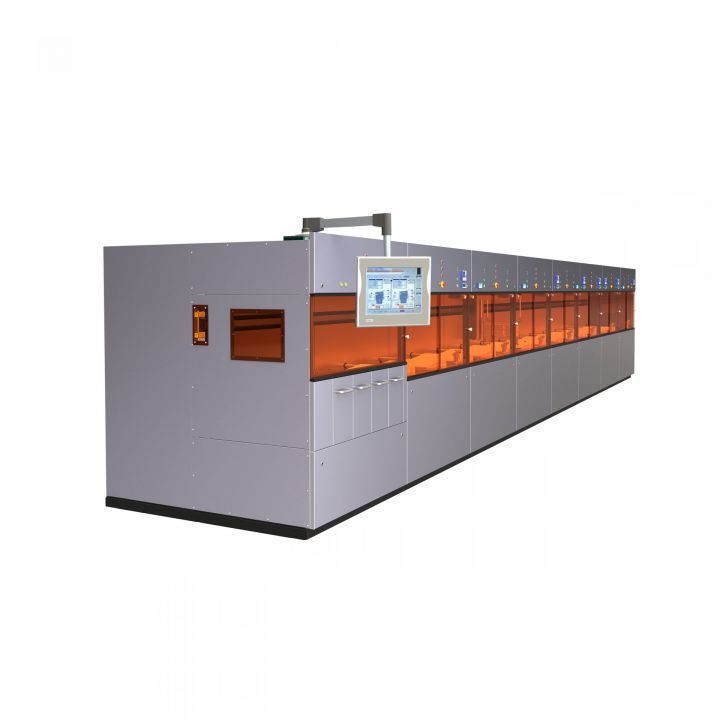

PacLine

The PacLine 300 A50 is a fully automated machine for electroless deposition of Ni/Au, NiPd or NiPdAu bumps on semiconductor wafers.

LaPlace – FC

The LaPlace-System provides an integrated solution for flip chip assembly for laser assisted soldering, ACF and NCP interconnections.

SB² – Jet

SB²-Jet is the machine with the highest placement precision and smallest solder ball capability.