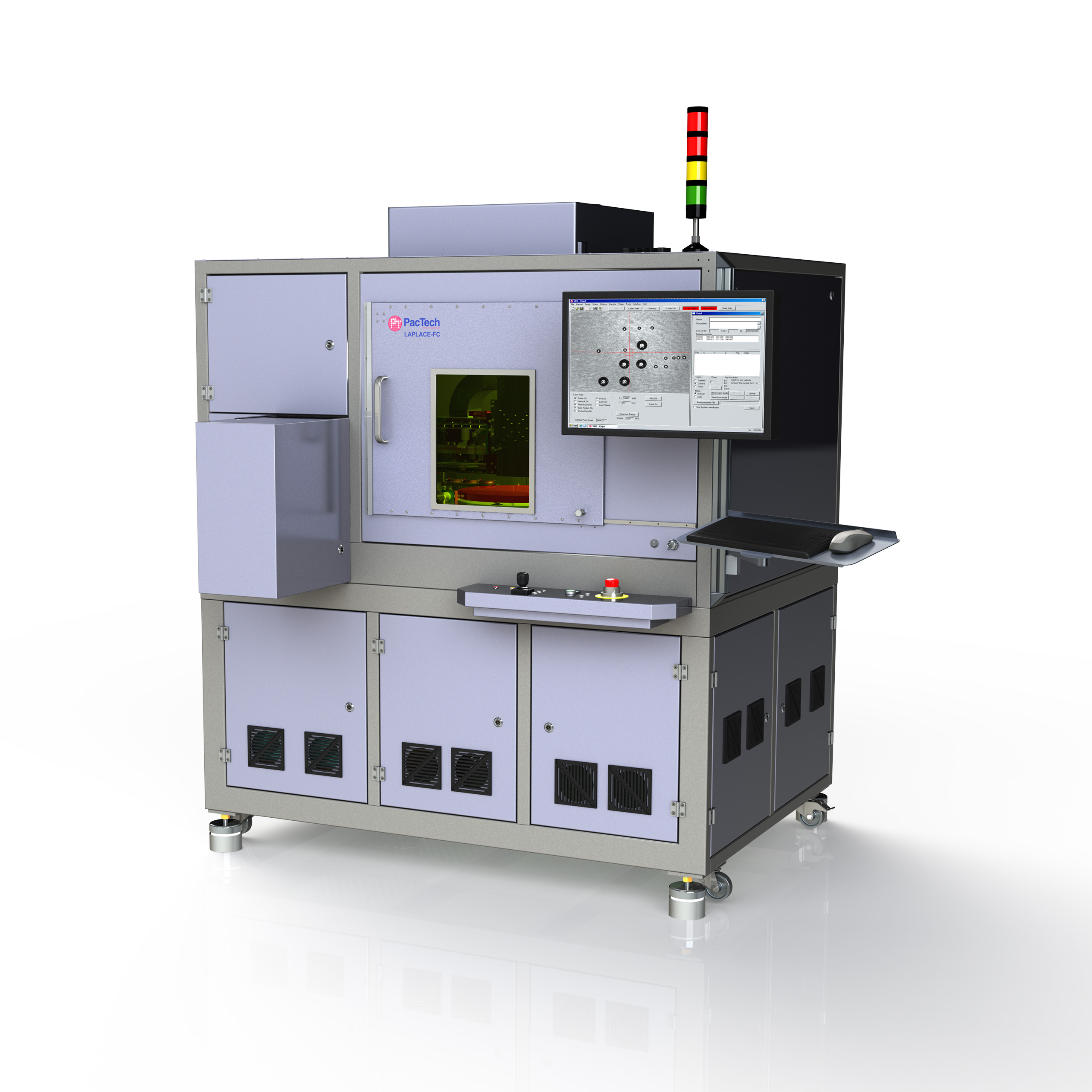

INTEGRATED FLIP CHIP ASSEMBLY MACHINE

LaPlace – FC

In the realm of advanced semiconductor packaging, the LaPlace – FC stands as a pinnacle of innovation, offering a comprehensive solution for flip chip assembly. Leveraging laser-assisted assembly techniques, this state-of-the-art system excels in soldering, ACF, and NCP interconnections with unmatched precision and reliability.

Integrated Flexibility:

At the heart of the LaPlace – FC is its seamless integration of flip chip placement, reflow, and curing in a single step. The optional dispensing unit further enhances the platform’s versatility, accommodating various materials such as flux, solder paste, and ACF or NCP dispense. This integrated flexibility empowers manufacturers with a holistic solution for diverse assembly requirements.

Flux-Free Reflow with Laser:

One of the standout features of the LaPlace – FC is its ability to achieve flux-free reflow through laser technology. This not only streamlines the assembly process but also eliminates the need for additional reflow or curing steps. The result is a more efficient and cost-effective approach to flip chip soldering and adhesive flip chip processes, including ACF, NCP, and ICA.

Material Compatibility:

The LaPlace – FC is designed to accommodate a variety of substrate materials, including PI, PVC, PE, Polyester, and paper-based low-cost substrates, among standard organic substrates. This wide-ranging material compatibility ensures that the system adapts seamlessly to diverse manufacturing needs.

Options for Optimization:

Tailoring the LaPlace – FC to specific requirements is made possible through customizable options, including Wafer Handling Systems, Reel to Reel Units, and Dispenser Systems. These options enhance the system’s adaptability, allowing manufacturers to optimize their processes according to the demands of their production environments.

Performance Benefits:

The LaPlace – FC offers a range of benefits, including in-line capability, high throughput, and different accuracy specifications from ±25µm down to ±1µm. Equipped with a Vision System, Temperature Control Unit, and boasting Laser Class 1 certification, this system ensures top-notch performance while adhering to stringent safety standards.

Diverse Applications and Product Compatibility:

The LaPlace – FC finds its application across various industries, including the assembly of sensors, MEMS, RFID devices and many others. Its versatility extends to applications such as flip chip assembly, flex-to-flex bonding, and flip chip rework, making it a comprehensive solution for a wide array of manufacturing needs.

In summary, the LaPlace – FC is not just a machine; it’s a technological marvel that redefines the landscape of flip chip assembly, providing manufacturers with a robust, flexible, and high-performance solution for the challenges of modern semiconductor packaging.

Highlights