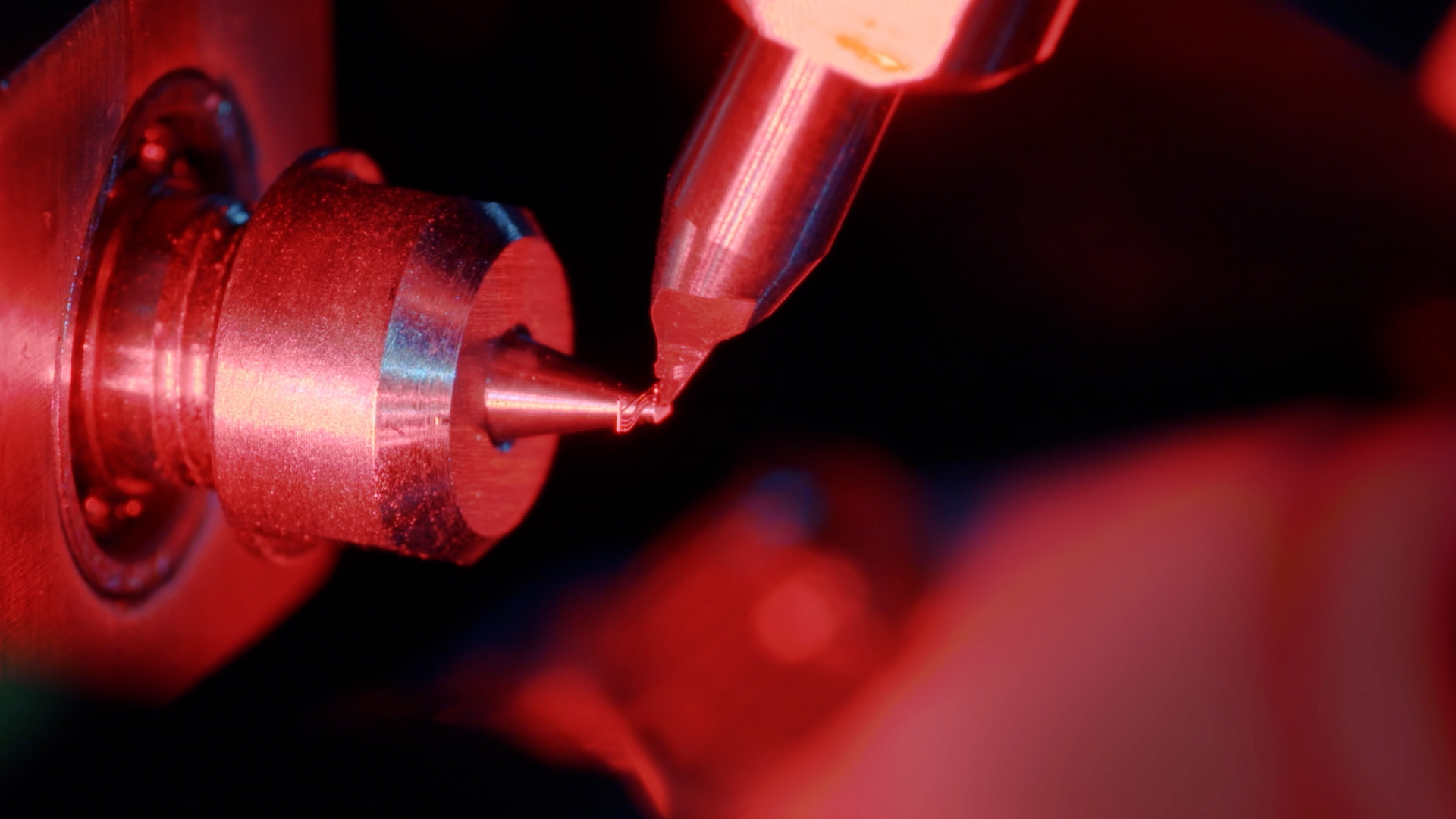

LASER ASSISTED BONDING SERVICE

The majority of today’s Flip chip bonders are derived from modified surface mount equipment. This method of flip chip attach uses thermal energy to reflow the bumped chip to the substrate. The advantage of laser heating instead of direct thermal heating is given by high selectivity with an extremely good time control in the millisecond time range. This is in contrast to infrared and convection ovens where the assembly process takes minutes. By using the laser to reflow the solder bumps, the thermal stress induced in the package and on the substrate is minimized allowing implementation of new substrates and new IC’s which are thermally more sensitive.

Process cycle times are improved by the equipment concept of performing chip placement and assembly reflow simultaneously and the absence of long heating and cooling cycles of standard TCB bonder systems. Beside of this the process capability for ACF, NCP and solder interconnection techniques illustrates the high flexibility of the laser heating process.