3D Package Machines for Interconnecting Dies/Chips On Wafers

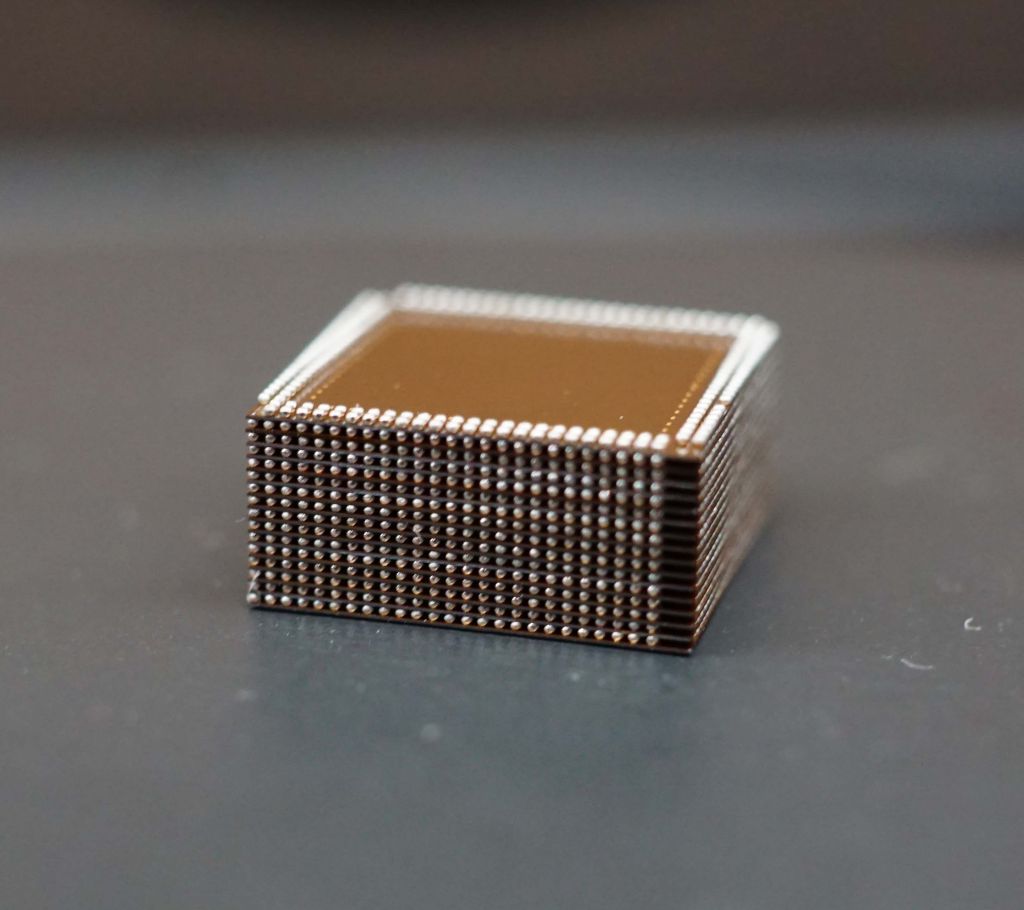

3D packaging enables stacking of multiple chips that communicate with each other and is part of 3D integration through horizontal as well as vertical connections.

This method provides a more compact way to further improve the performance of a chip while reducing cost and power consumption. The following methods are used in manufacturing, with various advantages and disadvantages:

3D Package Equipment

SB² – SMs Quantum

SB²-SMs Quantum is highly recommended solution for high volume production. It achieves high throughput with dual loading station/drawer system that realize continuous production.

SB² – Compact

SB²-Compact machine is the SB² entry point for high volume production with highly flexible and ultra-compact workstation.

SB² – Jet

SB²-Jet is the machine with the highest placement precision and smallest solder ball capability.

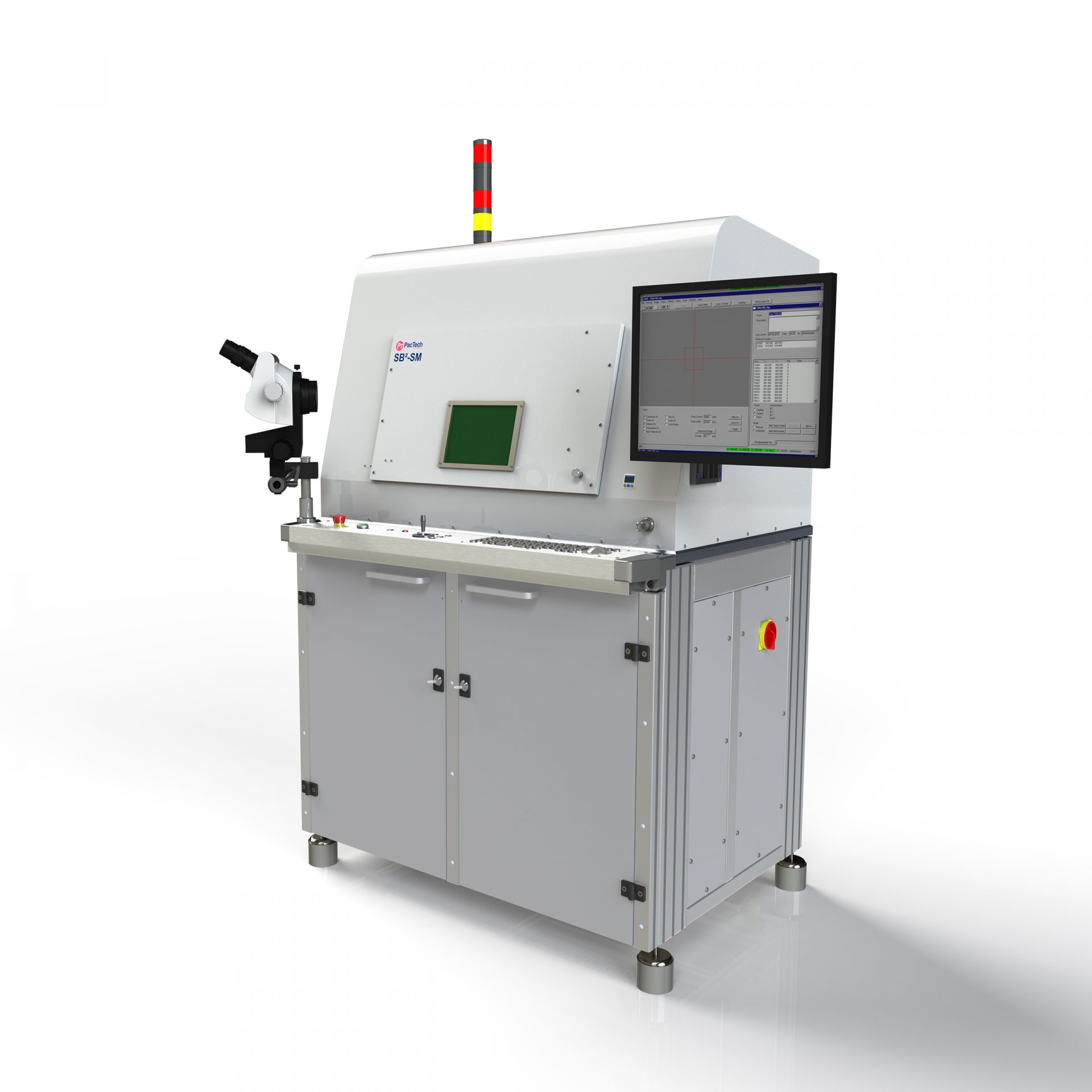

SB² – SM

The SB2-SM is a machine for prototyping and small volume production that has wider working area than the SB2-M and more optional features.

SB² – WB

SB²-WB is a combination of PacTech’s unique solder ball jetting machines with a wire feeding mechanism to perform wiring process.