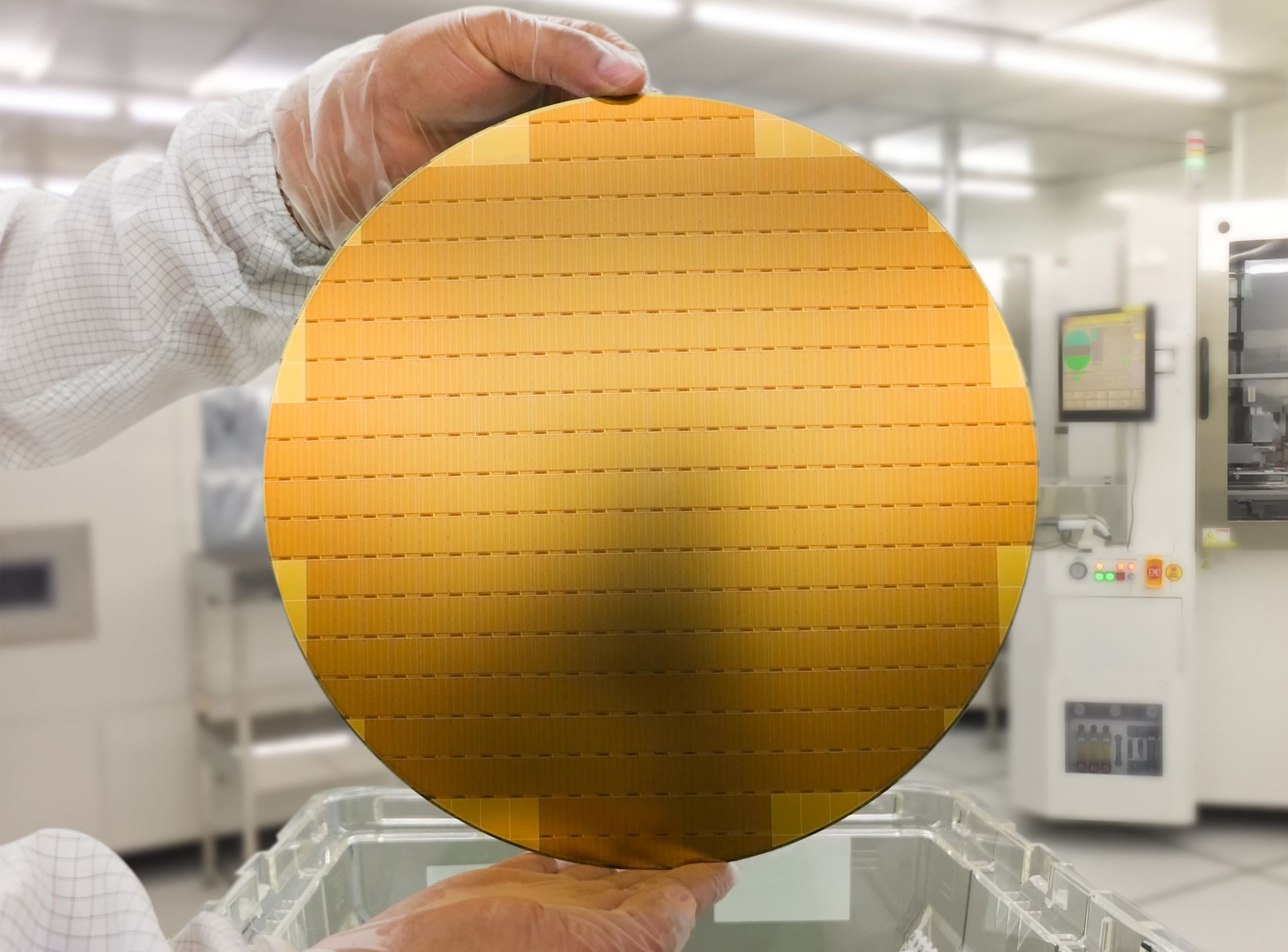

WAFER METAL COATING SERVICE

For better chip performance in terms of contact resistance and heat dissipation, metallizing the backside of the wafer has proven to be very effective. PacTech Asia uses an e-beam evaporation technology for its wafer backside metallization. The benefits of this technology are speed and low contamination as only the electron beam touches the source material.

We have the capability of coating metals on wafers using the evaporation process with less than 20% variation on the metal thickness (wafer-to-wafer as well as within the overall wafer). This process deposits single or multi-layer of thin metal films on controlled thickness using an electron beam gun (e-gun) evaporation source. We also provide options of mirror and matte finish depending on customer’s requirement.