LASER ASSISTED BONDING MACHINE – LAPLACE

Using localized laser heating mechanism, temperature can be applied selectively in the interconnection areas of interest without heating up the entire substrate up to the reflow temperature to liquefy and reflow an interconnection of a few microns. With customized bond tool and laser technology, pick-and-place and assembly reflow heating are accomplished in single step at high accuracy <5µm. Localized heat ensures reliable bonding of large dies while the in-situ reflow supports ultra-small die assembly as small as 300µm.

Our unique temperature control mechanism protects single chip or component from being over-heated and prevents substrate from warpage and repeating reflow circumstances.

Highlights

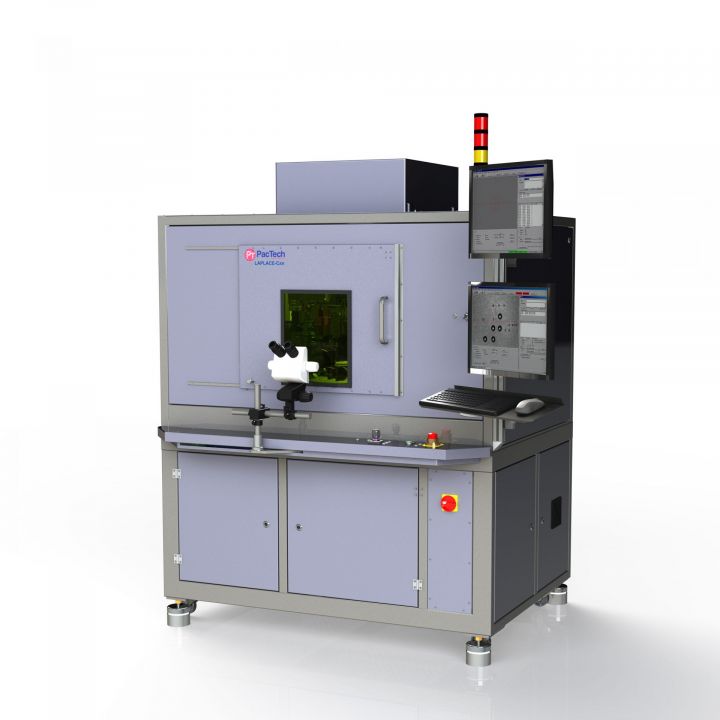

LaPlace – Equipment

LaPlace – Can

Ultra-Fine-Pitch Cantilever Assembly and Laser Bonding for Wafer Probe Cards with optional Rework Capability.

LaPlace – FC

The LaPlace-System provides an integrated solution for flip chip assembly for laser assisted soldering, ACF and NCP interconnections.

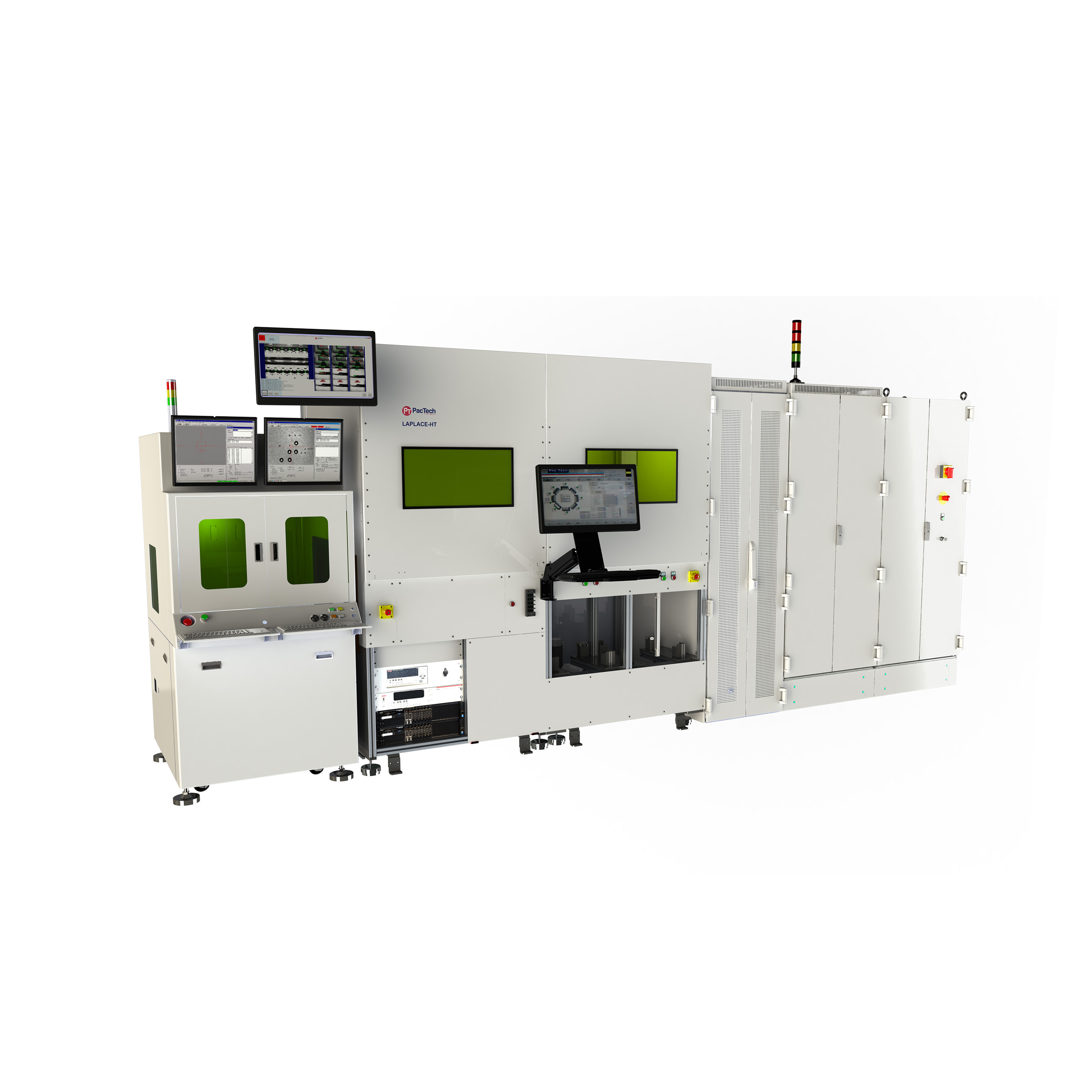

LaPlace – HT

The LaPlace-HT is an automatic Laser Soldering machine for assembly of e.g. Schottky Diodes and Bypass Diodes – especially for solar cell modules.

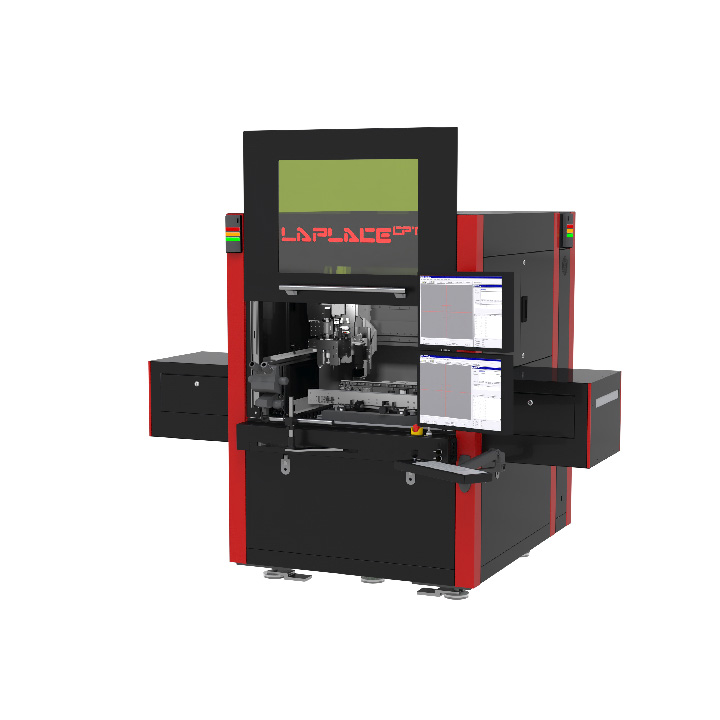

LaPlace – CPT

Laser Bonding System (LAB) with Compression Bonding and Laser Assisted Reflow.

LaPlace – VC

The LaPlace-VC laser bonder is a system for the vertical attachment of chips or similar devices loaded into the machine in wafer packs.