WAFER LEVEL COMPONENT ASSEMBLY SERVICE

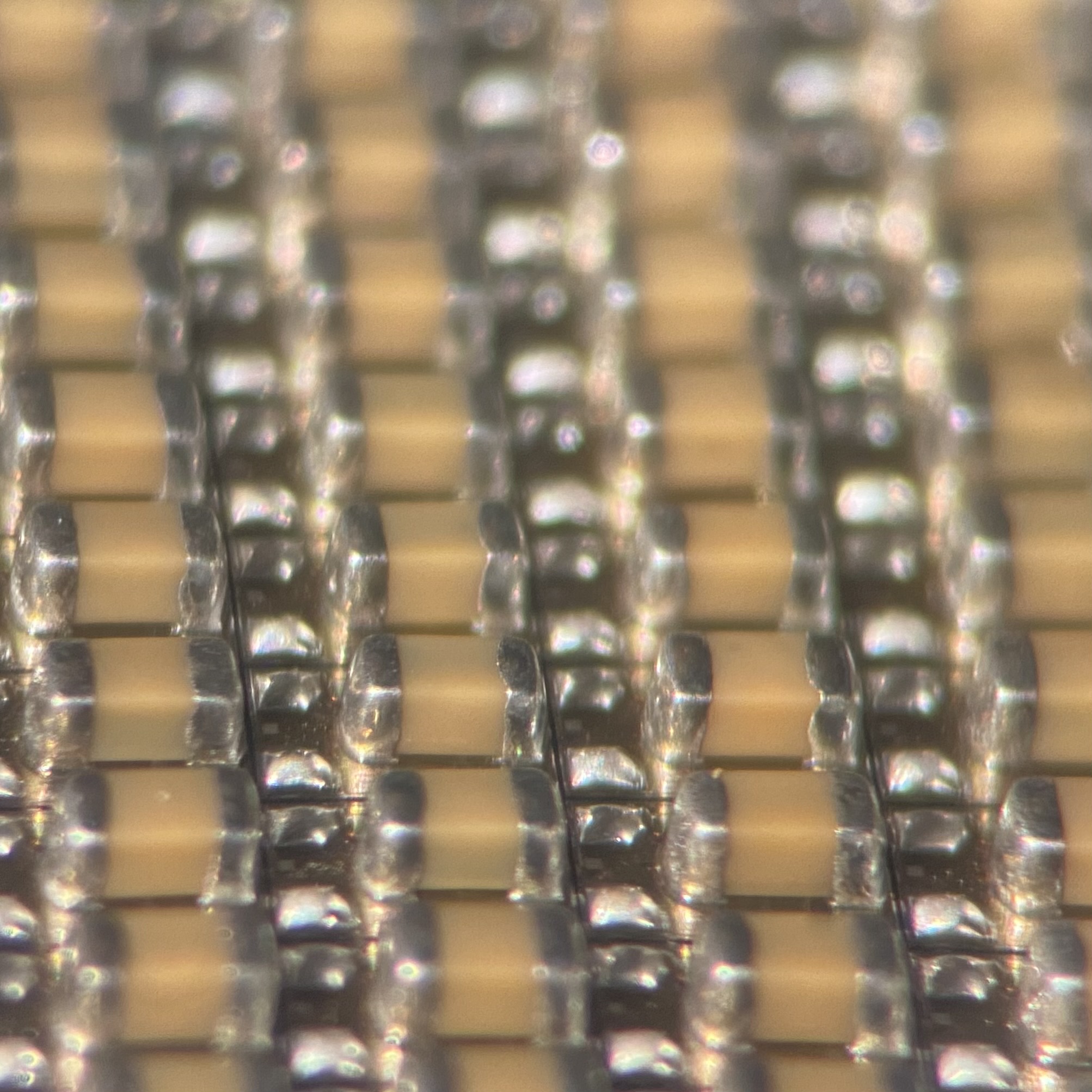

Wafer-level component assembly can result in significant cost savings and shorten cycle time while reducing package size. Our wafer-level component assembly includes solder application, component placement and reflow process, and optional optical inspection. The types of components that can be placed on the wafer include single chips, diodes, capacitors, transistors and other IPD that can directly form a package through wafer-level assembly. The wafer can then be cut into multiple dies and shipped either on a saw ring or taped onto reels for the rest of the assembly process.

Our wafer level component assembly services include: