PACKAGING TECHNOLOGIES

Who are we?

PacTech is a technology-focused company specialized in advanced packaging equipment manufacturing and wafer level packaging services. Since our establishment, our team has been working relentlessly on developing new leading-edge technologies for the next generation applications. We are known to be highly adaptive to customization and unique applications. Our team of technical experts is striving to resolve various packaging challenges faced by the industry to provide our customers and partners more competitive solutions in terms of cost, time-to-market, and technology advancement. Our headquarter is located in Nauen, Germany with two operation and manufacturing sites in Santa Clara, CA, USA and Penang, Malaysia. Together with our sales and field service teams across the globe, we can cater to the demand within your region.

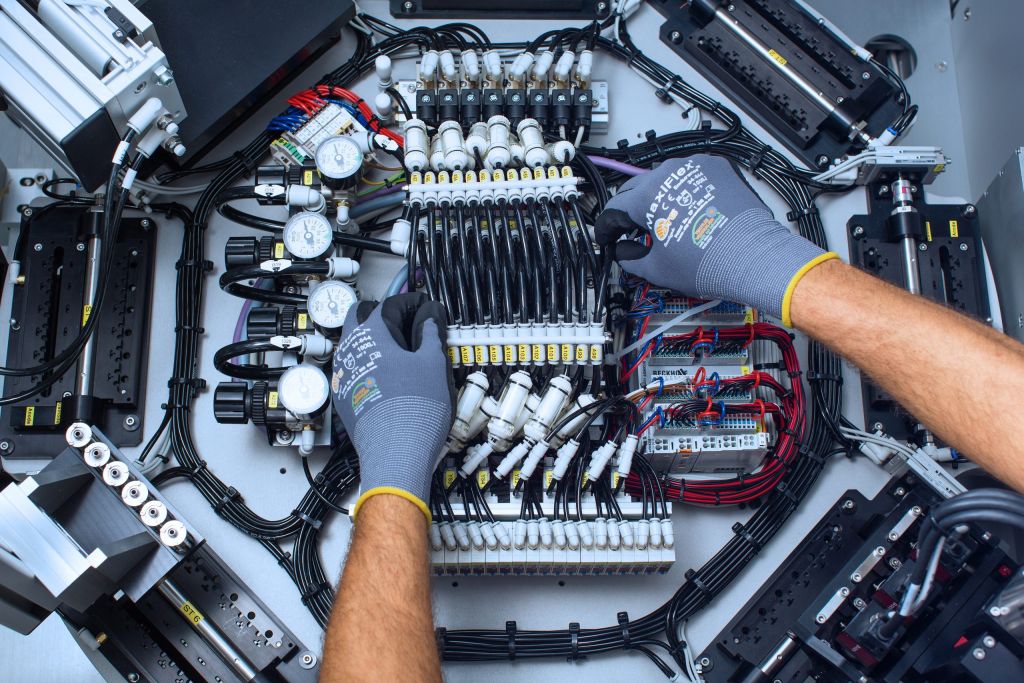

ADVANCED PACKAGING EQUIPMENT

Our advanced packaging equipment portfolio incorporates several core technologies including laser soldering and wire soldering, laser assisted bonding and innovative wafer level bumping solutions such as electroless plating and wafer level ball placement. We offer equipment solutions for high throughput and fully automated manufacturing as well as advanced research and development field work.

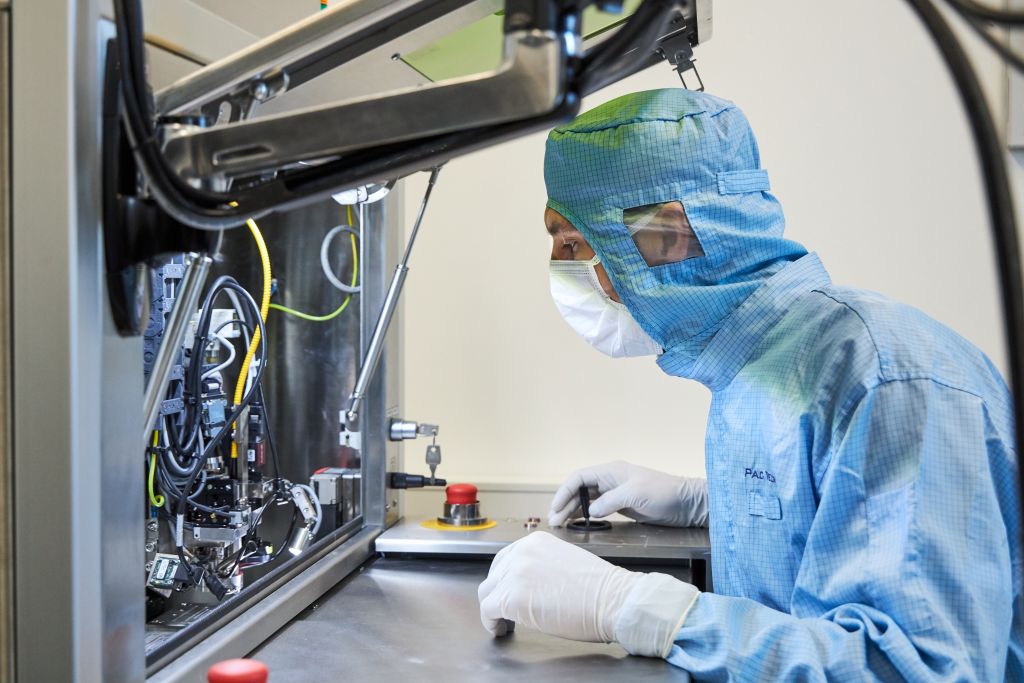

WAFER LEVEL PACKAGING SERVICES

With our state-of-the-art wafer level bumping, metallization, and advanced packaging processes PacTech supports the heterogeneous integration technology roadmap. In combination with our unique laser soldering and laser bonding equipment, PacTech is able to offer a variety of manufacturing and engineering solutions for the technical and economic challenges in today’s industry. Our manufacturing sites are ISO 9001 and IATF 16949 certified for highest level of quality and process control. Being a socially responsible company, we are also ISO 14001 and ISO 50001 certified for our operations.

Chemicals

As a turnkey solution provider for electroless plating, we are supplying complete process solutions to our customers by combining our plating know-how, equipment and process chemicals to guarantee a successful process transfer. Our plating chemicals are controlled by highest quality standards and are available throughout a worldwide distribution network to handle import and warehousing task, but also to provide technical onsite support to our customers.

PacTech History

1995 - Foundation

1997 - 1st Manufacturing Facility

PacTech GmbH, Nauen, Germany

2001 - 2nd Manufacturing Facility

PacTech USA Inc., CA, USA

2003 - Key Supplier

for Hard Drive Soldering (HGA, HSA)

2008 - 3rd Manufacturing Facility

2012 - Key Supplier

for Camera Module Soldering

2015 - Demo Center

Opening in Shanghai, China

2015 - 100% Owned

by Nagase & Co. Ltd.

2017 - Key Supplier

for Solar Cell Production in China

2022 - Achievements to Date

> 2.000 Production Machines shipped

> 165 patents granted

~ 420 employees

PacTech Management

Dr. Thorsten Teutsch

Managing Director | CEO

Annette Burczyk

Managing Director | CFO

Thomas Oppert

Vice President | Sales

Matthias Fettke

Vice President | Advanced Packaging Equipment

Sy Jiun Sim

Vice President | Wafer Level Packaging

Thorsten Krause

Director Equipment Technology

Ricardo Geelhaar

Director WLP Technology