Solder Ball Mounting Machines for WLCSP & Flip Chip Packaging

Ball mounting is a sort of the most popular method to create solder bumps onto a high I/O substrate like a semiconductor wafer. In comparison with the other types of soldering method including laser soldering, this type of process shows better performance for a high I/O substrate. Our ball mounting machine has 4 process steps:

Depending on the requirement, you could choose from these functional modules and a customized machine is able to be built. Besides the solder ball mounting, we provide reflow process as a part of bumping service.

Solder Ball Mounting Equipment

Ultra – SB²

Ultra-SB2 is a fully automated solder bumping equipment integrating flux printing, ball placement, 2D inspection and wafer level rework.

SB² – Jet

SB²-Jet is the machine with the highest placement precision and smallest solder ball capability.

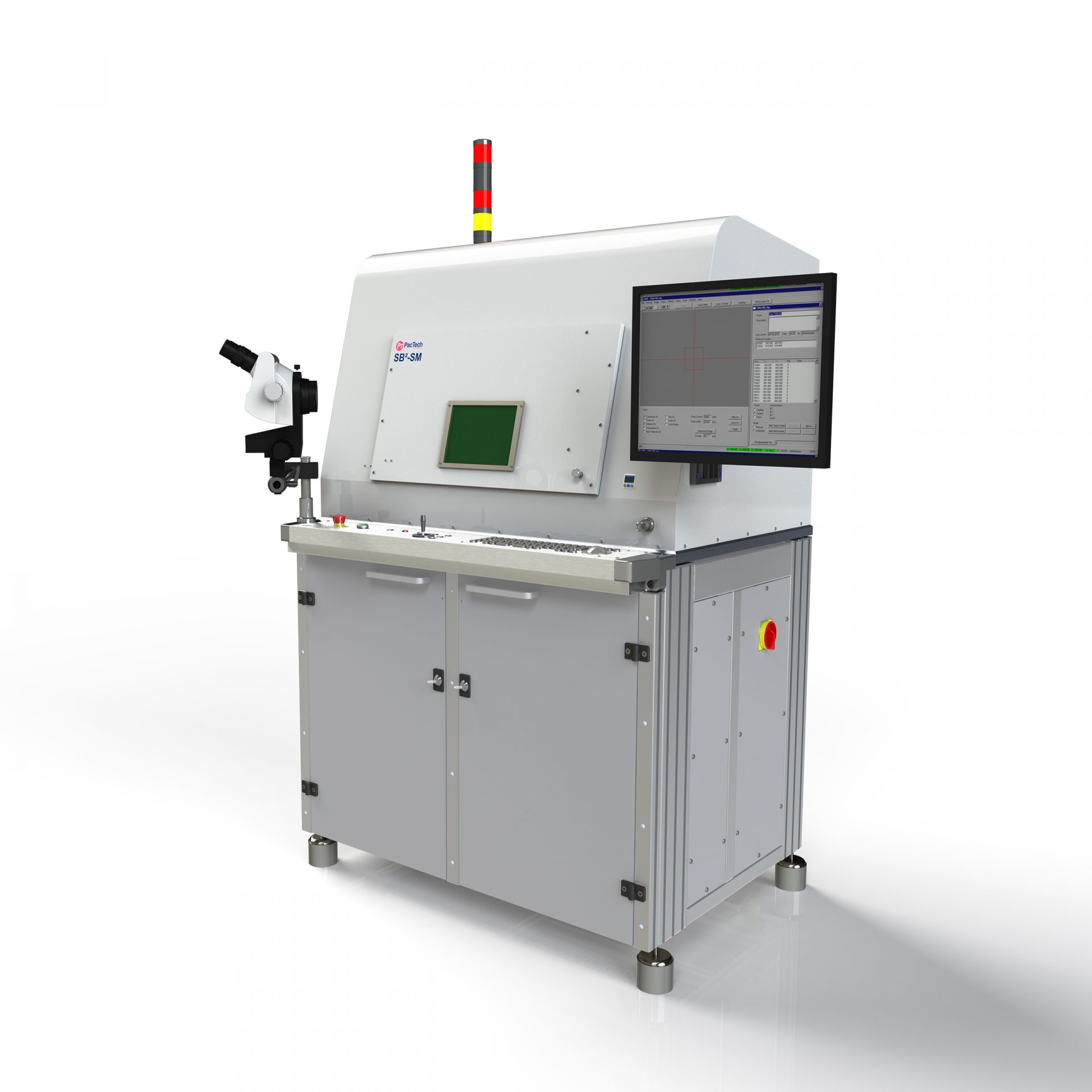

SB² – SM

The SB2-SM is a machine for prototyping and small volume production that has wider working area than the SB2-M and more optional features.

SB² – Compact

SB²-Compact machine is the SB² entry point for high volume production with highly flexible and ultra-compact workstation.