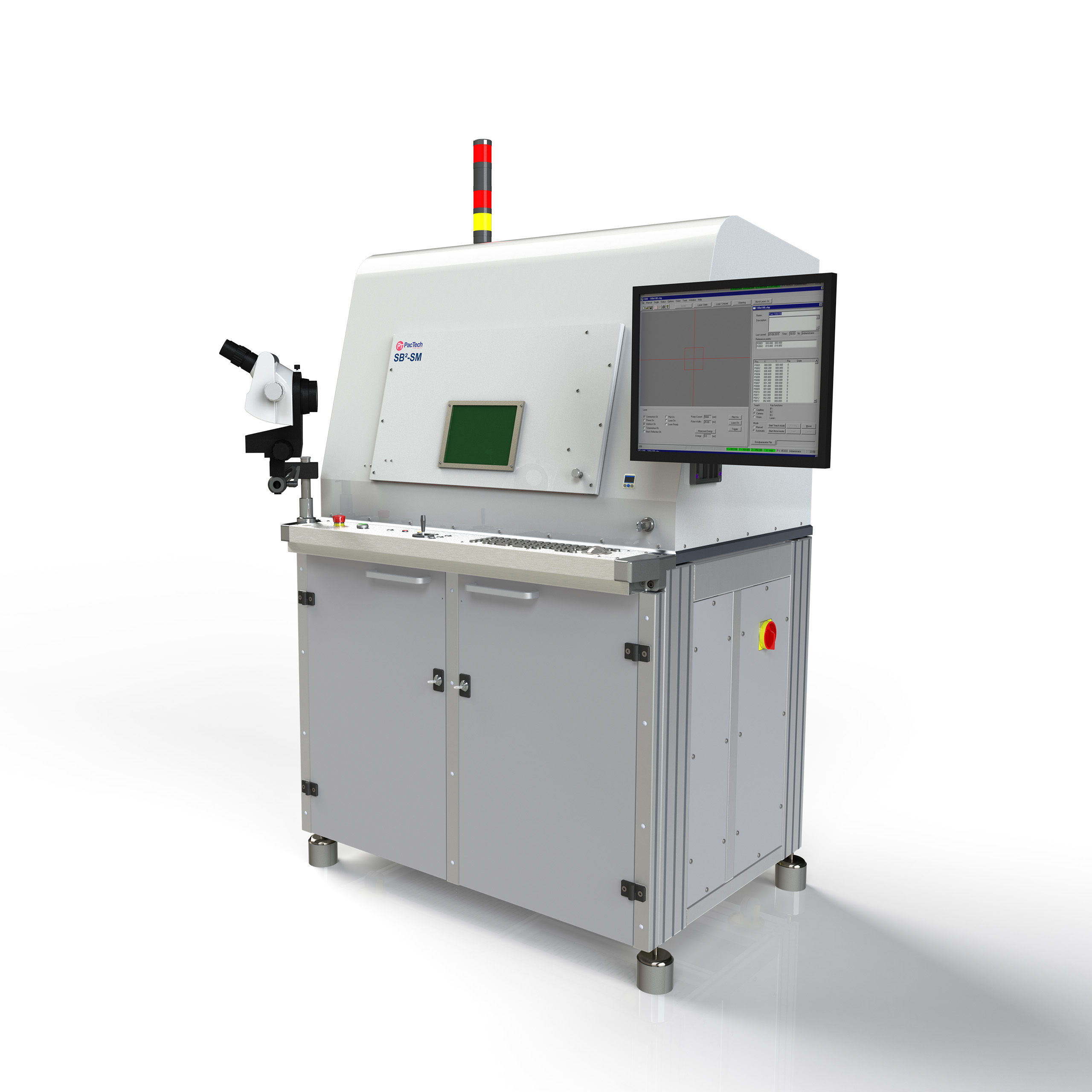

SEQUENTIAL SOLDER BALL ATTACH MACHINE

SB² – SM

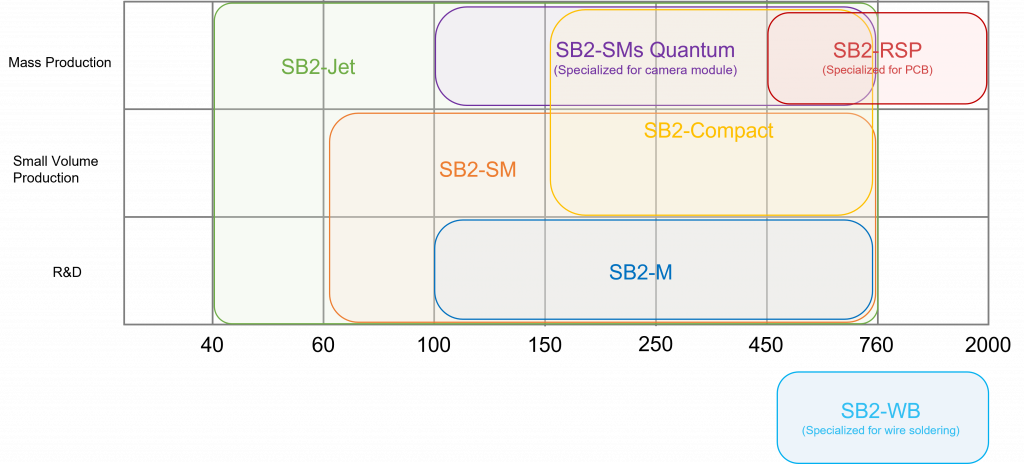

Being a lower cost version of the SB²-Jet without compromising its placement accuracy, the SB²-SM is a sequential solder ball attach and laser reflow system that can operate either in a fully automatic or in a semiautomatic mode. With larger work area than the SB²-M, yet relatively compact foot print than the SB²-Jet, it is ideal for research & development, prototyping and small volume manufacturing.

Highlights

Options

Benefits