Reballing/Deballing for Repairing of Defective Solder Balls on BGA

In some cases, it is necessary to restore defective solder contacts on semiconductor devices. Our equipment offers different application methods:

Repair

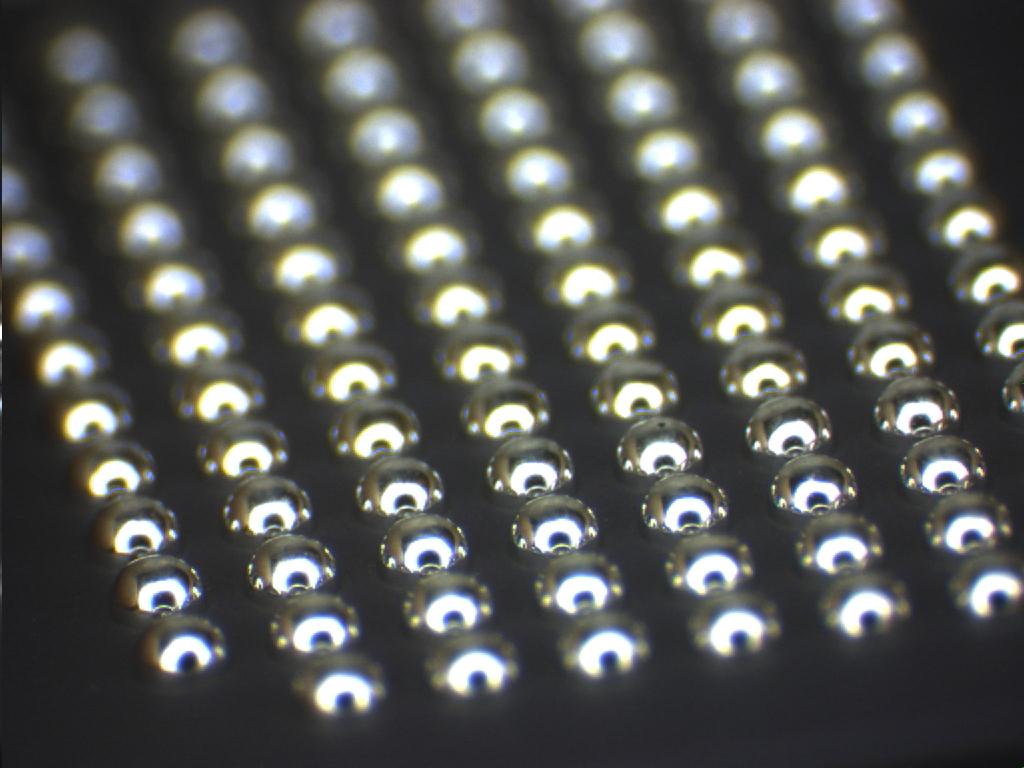

Repairing is used for missing or excessive solder balls on contact pads during the bumping upfront the reflow process. Yield loss can happen during paste printing, solder paste dispensing, solder ball single placement or multi sphere transfer. For most applications, bump yield losses impact the overall profit margin, especially on devices of high value with a high input/output count per die. Using an inline repair station which removes excessive balls or places spheres on missing pad locations, the ball placement yield is dramatically increasing for an efficient reflow result.

Rework

Reworking solder bumps is needed when parts get damaged during the assembly of semiconductor products like ball grid arrays (BGA), chip scale packages (CSP) or flip chip packages (FC). To rework these devices, disassembly of the individual components is necessary. This includes the removal of damaged solder bumps from the device and substrate to replace them with new ones. A flexible rework tool can handle these parts for a significant increase of the overall system yields.

Reballing/Deballing

When the replacement of lead-free balls with leaded balls is required for special applications, the process is referred to as reballing. Most BGA producing backend packaging companies switched to lead-free alloys (SnAgCu), leaving specialty applications like defense, aerospace and medical without the qualified lead-based BGAs required for their systems.

The processes of rework and reballing/deballing (also, repairing through an extension) can be performed by our SB² laser based bumping systems, which removes and replaces solder bumps utilizing a local heating source to selectively melt a single solder sphere, then uses a vacuum to remove the molten solder material from devices like a wafer, chip, or package. The SB² then drops a new preformed solder sphere onto the bond pad while simultaneously reflowing the sphere through our laser solder jetting process.

Solder Ball Rework Equipment

SB² – Jet

SB²-Jet is the machine with the highest placement precision and smallest solder ball capability.

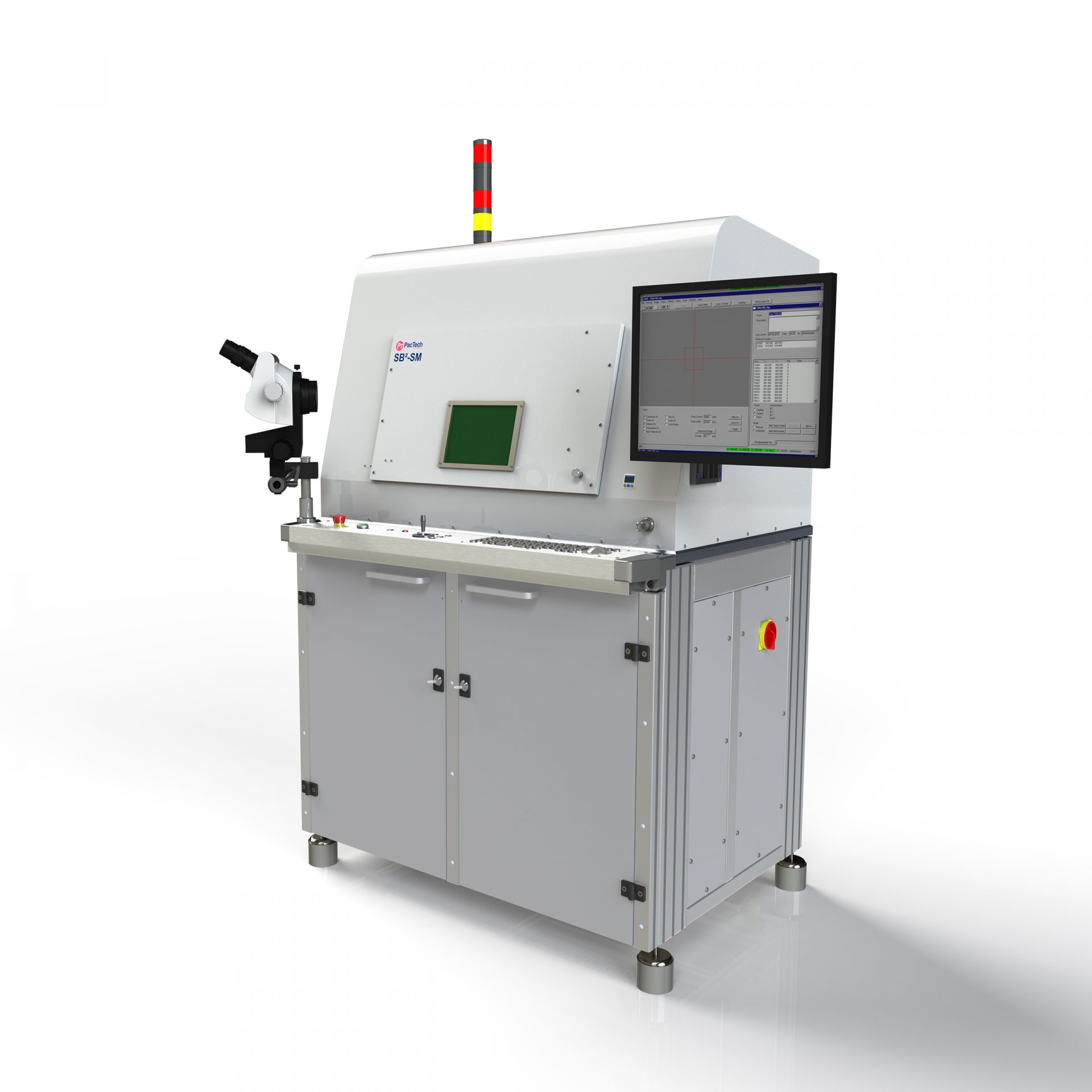

SB² – SM

The SB2-SM is a machine for prototyping and small volume production that has wider working area than the SB2-M and more optional features.

SB² – Compact

SB²-Compact machine is the SB² entry point for high volume production with highly flexible and ultra-compact workstation.