COPPER PILLAR SERVICE

The advance packaging roadmap has demanded for smaller pitch and bump diameter while maintaining the same package height. Cu pillar bumping can cater to the demand of refining package size with better electromigration performance, alongside with other benefits such as RoHS compliance, higher cost efficiency and shorter cycle time.

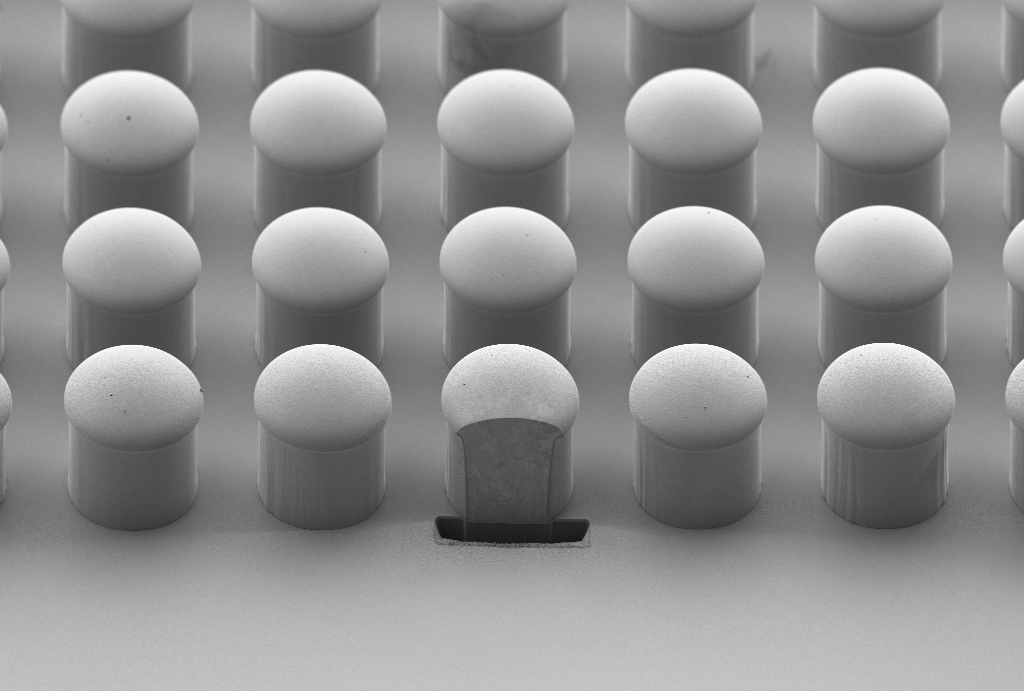

PacTech offers solution for fine pitch Flip Chip and WLCSP with Cu pillar bumps, our Cu pillar line-up comes with various finishes with individual advantages:

Our Cu pillars come with optional passivation such as PI, suitable for various applications such as 5G & RF, automotive, consumer, power controller and sensor.