Laser Soldering Machines for Advanced Packaging of Chips/Dies

Soldering is one of the most common process in the various industries such as semiconductor, electrical component, optical component, and more. Despite the long history of the process, soldering is still to the best way to get robust mechanical and electrical interconnection even today.

Our unique soldering solution “Solder Jetting / Jet Mode” provides you a wide range of flexibility that allow you to deal with the difficulties stem from the nature of your products.

Depending on the condition of the products, you can also choose the soldering mode “Standard Mode” that even expand the capability of the machines.

Laser Soldering Process

Choose the bonding mode that best suits your application.

Jet Mode

Standard Mode

Laser Soldering Equipment

SB² ® – Jet

SB² ® - Jet offers the highest placement precision of all PacTech machines and is capable of processing the smallest solder balls in the portfolio.

SB² ® – SMs Quantum

SB² ® - SMs Quantum is highly recommended solution for high volume production. It achieves high throughput with dual loading station/drawer system that realize continuous production.

SB² ® – Compact

SB² ® – Compact machine is the SB² ® entry point for high volume production with highly flexible and ultra-compact workstation.

SB² ® – WB

SB² ® - WB is a combination of PacTech’s unique solder ball jetting machines with a wire feeding mechanism to perform wiring process.

LAPLACE ® – HT

The LAPLACE ® - HT is an automatic Laser Soldering machine for assembly of e.g. Schottky Diodes and Bypass Diodes – especially for solar cell modules.

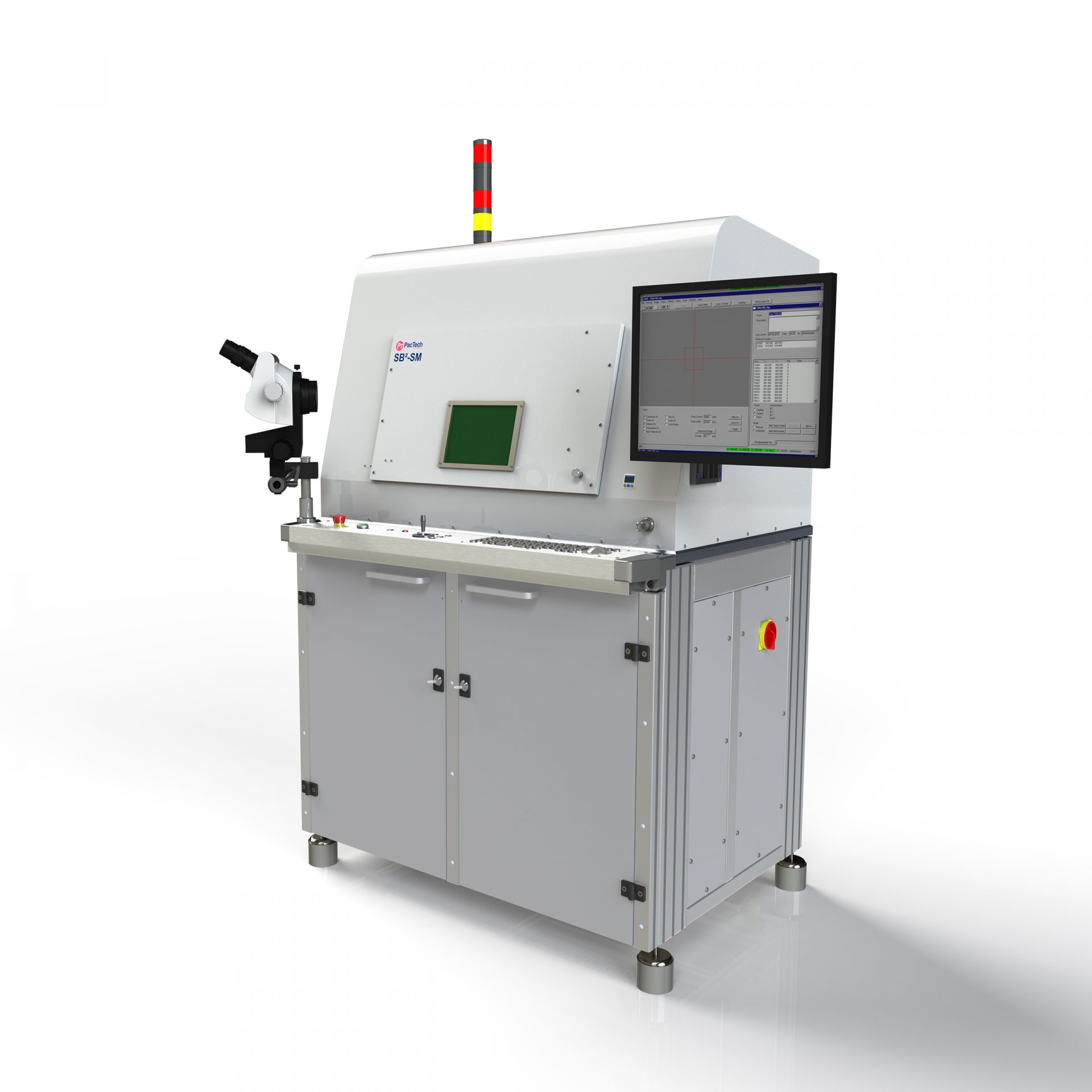

SB² ® – SM

The SB² ® - SM is a machine for prototyping and small volume production that has wider working area than the SB² ® - M and more optional features.

SB² ® – USP

Highly flexible laser soldering and assembly platform for SMT components, especially for high-volume production in the automotive industry.