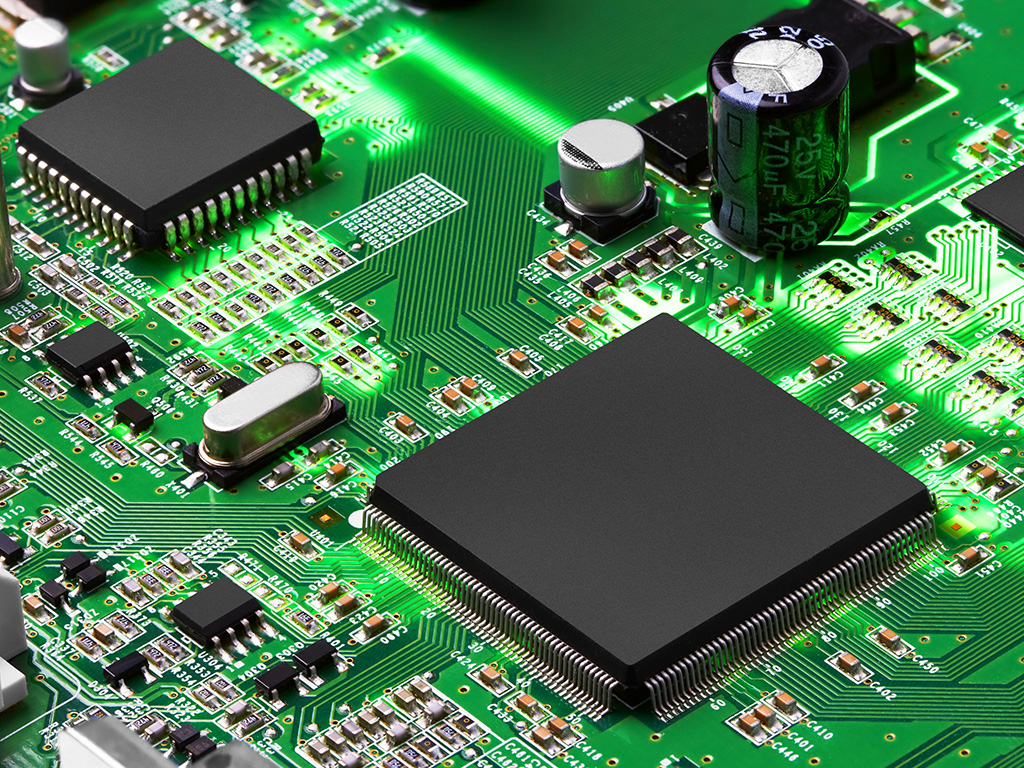

Advanced Packaging Machines for the Production and Assembly Industry

In the production and assemlby industry, it is important that any electronic components function reliably and properly. For ideal processing in the field of advanced packaging of, for example, computer hardware components, PacTech offers suitable equipment for applications such as:

PacTech’s products allow for a high degree of precision and performance in advanced packaging applications. Take a look at our equipment for production and assembly applications below to learn more about our products and how you can benefit your business.

Equipment for the Production/Assembly Industry

SB² ® – USP

Highly flexible laser soldering and assembly platform for SMT components, especially for high-volume production in the automotive industry.

SB² ® – WB

SB² ® - WB is a combination of PacTech’s unique solder ball jetting machines with a wire feeding mechanism to perform wiring process.

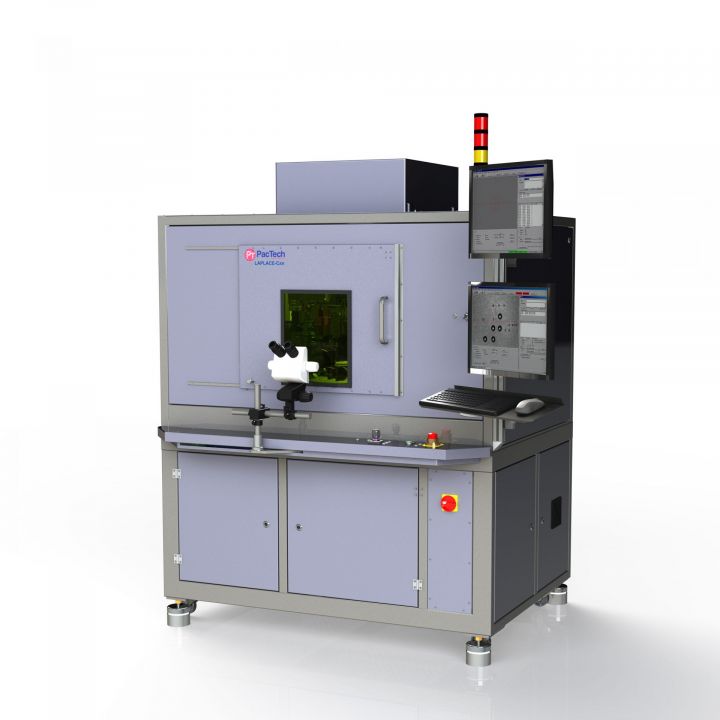

LAPLACE ® – 3.5D ®

The LAPLACE ® - 3.5D ® laser-assisted bonding platform is our solution for ultra-fine-pitch cantilever assembly on wafer probe cards with optional rework capability.

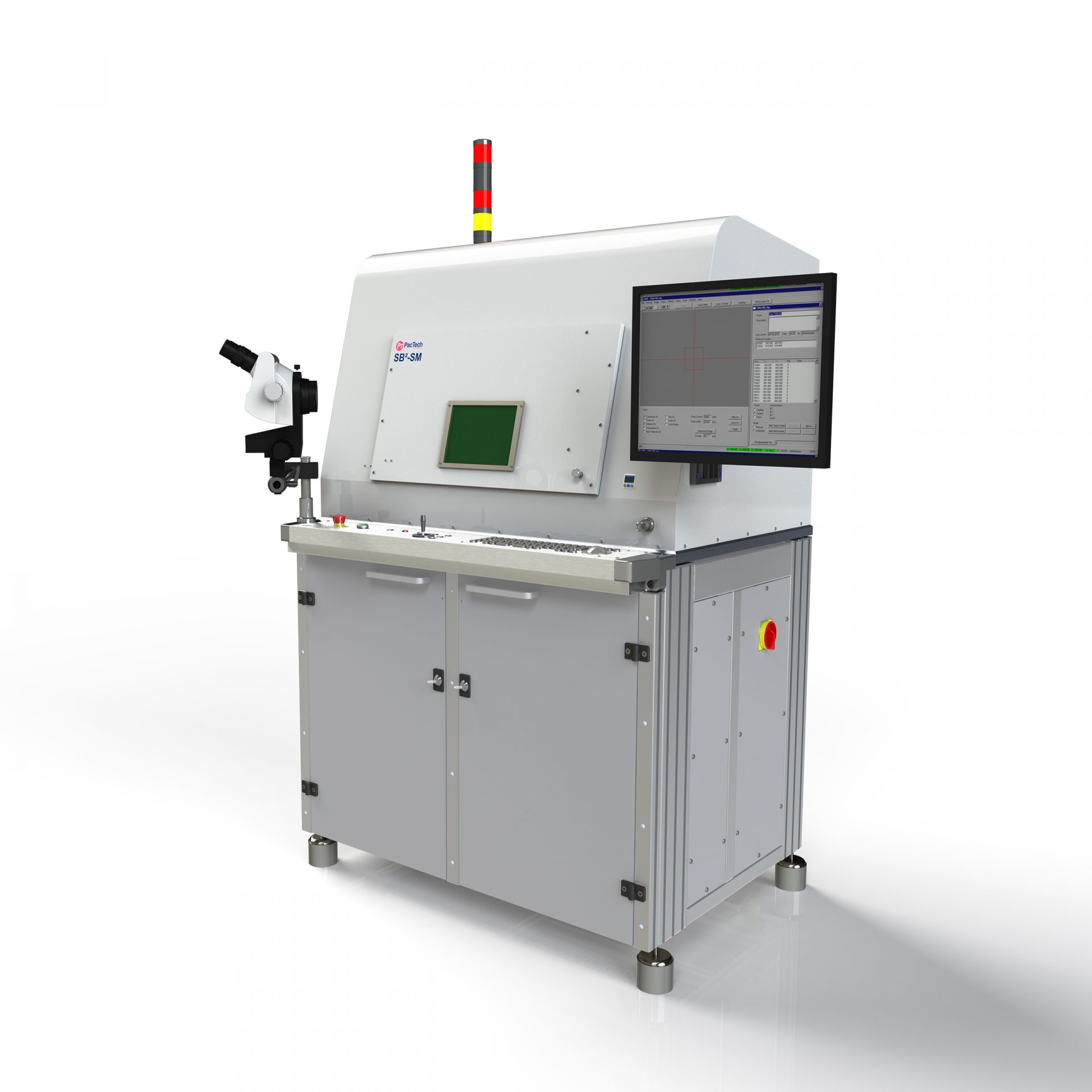

SB² ® – SM

The SB² ® - SM is a machine for prototyping and small volume production that has wider working area than the SB² ® - M and more optional features.

LAPLACE ® – LAB 300A

The LAPLACE ® - LAB 300A provides an integrated solution for flip chip assembly for laser assisted soldering, ACF and NCP interconnections.

SB² ® – Jet

SB² ® - Jet offers the highest placement precision of all PacTech machines and is capable of processing the smallest solder balls in the portfolio.

LAPLACE ® – HT

The LAPLACE ® - HT is an automatic Laser Soldering machine for assembly of e.g. Schottky Diodes and Bypass Diodes – especially for solar cell modules.

SB² ® – SMs Quantum

SB² ® - SMs Quantum is highly recommended solution for high volume production. It achieves high throughput with dual loading station/drawer system that realize continuous production.

SB² ® – Compact

SB² ® – Compact machine is the SB² ® entry point for high volume production with highly flexible and ultra-compact workstation.