SMT Machines for Electronical Component Assembly on PCB’s

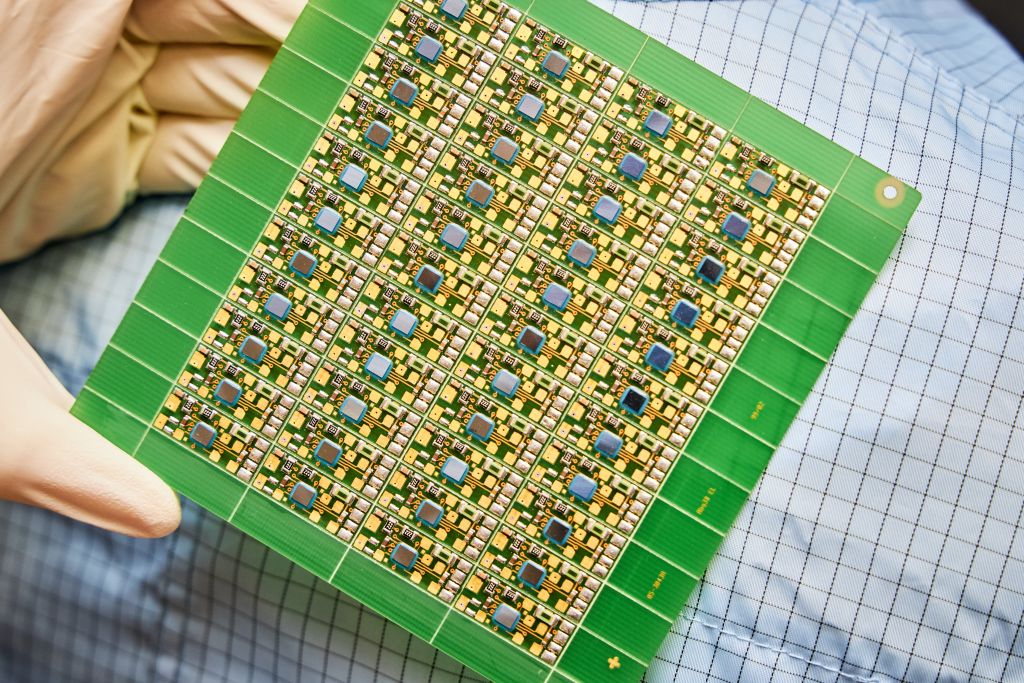

Surface Mount Technology (SMT) is one of the principal method to be used for assembling electronic components onto a substrate such as Printed Circuit Board (PCB). The device assembled with that method is called as Surface Mount Device (SMD).

In many cases, the components such as a capacitor is placed in appropriate position with mounter equipment, and the substrate is heated by a reflow oven to form a solder interconnection. This process expects high throughput, however, it gives too much thermal stress to the substrate as a downside.

Our laser assisted bonding equipment provides you a low thermal stress bonding process. It allows you to process following objects:

- Substrate has devices/components that easily affected by heat

- Substrate itself shows heat-sensitive characteristics

SMT Equipment

SB² – USP

Highly flexible laser soldering and assembly platform for SMT components, especially for high-volume production in the automotive industry.