HIGH-SPEED SOLDER BALL ATTACH AND LASER REFLOW MACHINE

SB² – Jet

Flagship platform of PacTech’s leading edge solder jetting technology with the high precision gantry is the most advanced system for automated high-speed sequential solder ball attach and laser reflow. With accurate, precise and reliable performance proven in mass volume production environment, the large working area of this model is highly flexible for a variety of different microelectronic substrates and applications. A comprehensive version of the SB²-Jet is delivered with a vision and pattern-recognition system, an after-bump 2D inspection and an additional repair unit, with optional automated substrate or wafer handling solution customizable to support customer-specific products and carriers such as conveyor, robot or reel-to-reel system, this machine is ready for in-line production integration.

Highlights

- Soldering mode: Jet mode/Standard mode

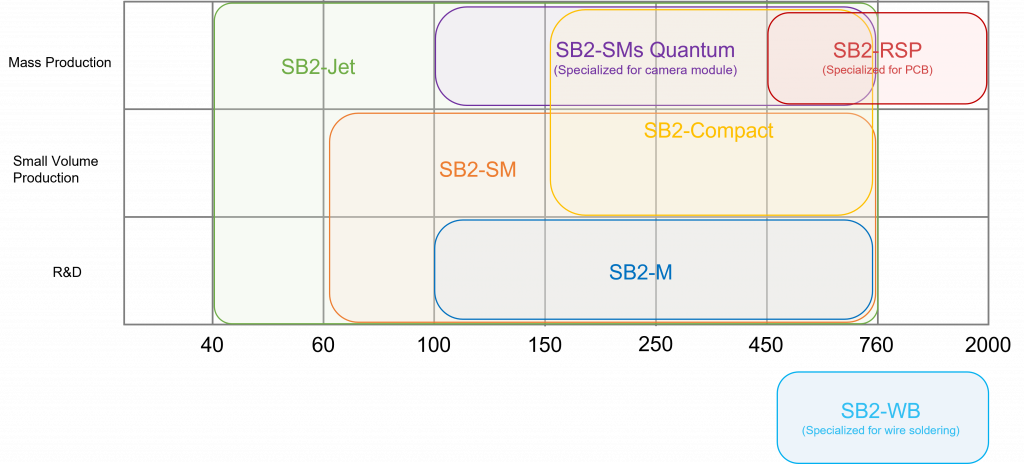

- Available solder ball diameter : 40 – 760μm

- Recommended soldering condition: 2D soldering

- Suitable for chip/wafer/substrate soldering

- In-line capability

- Optional ball rework (de-balling & re-balling) capability

- Ball Inspection System (2-D)

- Automatic Z-Height Measurement

- ESD Kit

- Heated chuck/work stage

- Specific heated work holder for BGA-like devices

- Solder Ball Rework Station

- Automatic Wafer Handling System 6”-12”

- Automatic Reel to Reel System

- Automatic Inline Conveyor System

- Expand working area > 320x320mm

- High accuracy

- Largest possible working area 320x320mm

- Small solder ball size capability

- Optional post vision inspection capability

SB² – Jet Products & Applications

Products

- MEMS & 3D Package

- Camera Modules

- CMOS Sensors

- Hard Disk Drives (HDD)

- Opto-Electronics

- Microoptics

Applications

- Hard Disk Drive Assembly

- 3D Solder Jetting

- Chip Scale Packaging

- Flip Chip

- Single Chip

- Ball Grid Array (BGA)

- Printed Circuit Board (PCB)

- Repair/Rework