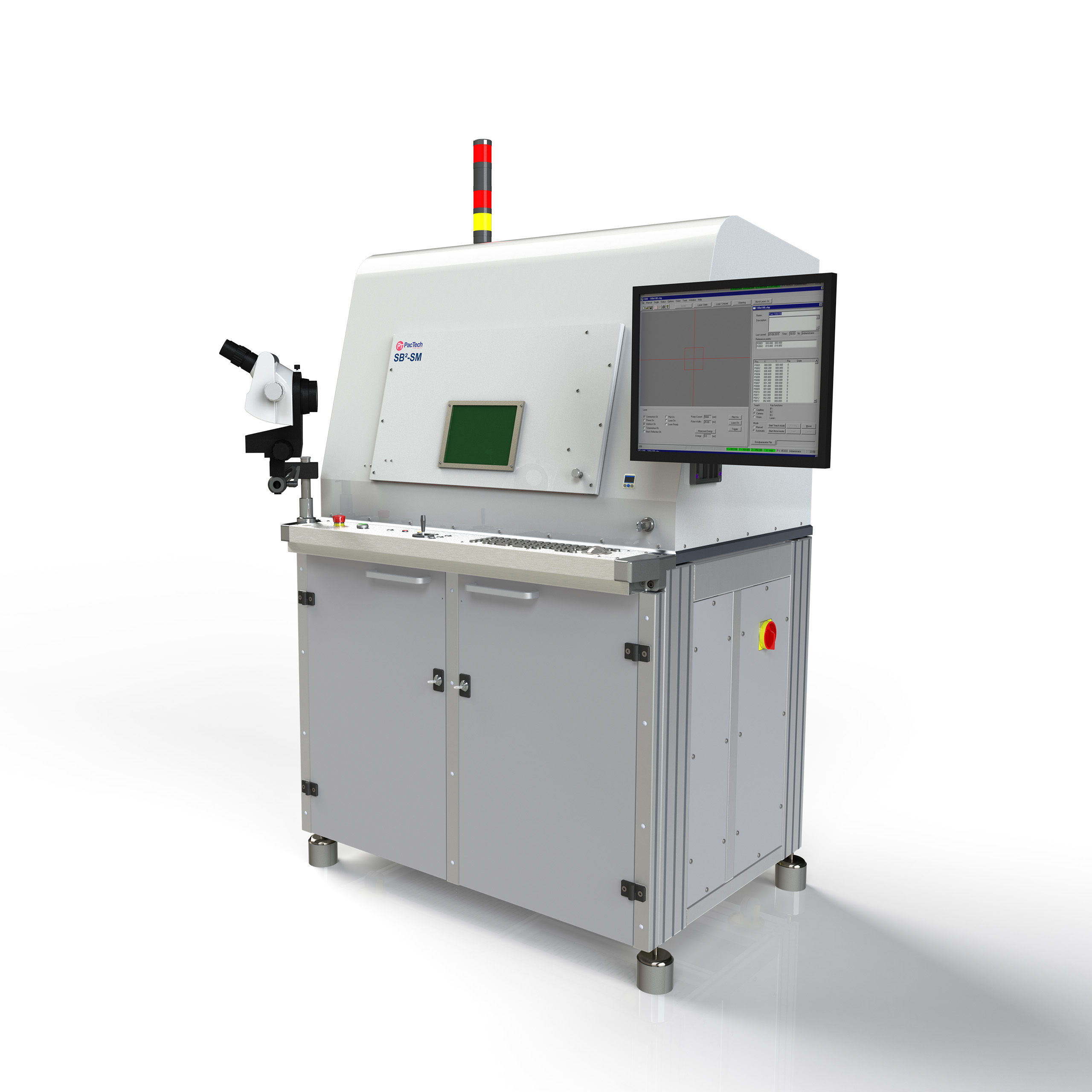

SEQUENTIAL SOLDER BALL ATTACH MACHINE

SB² – SM

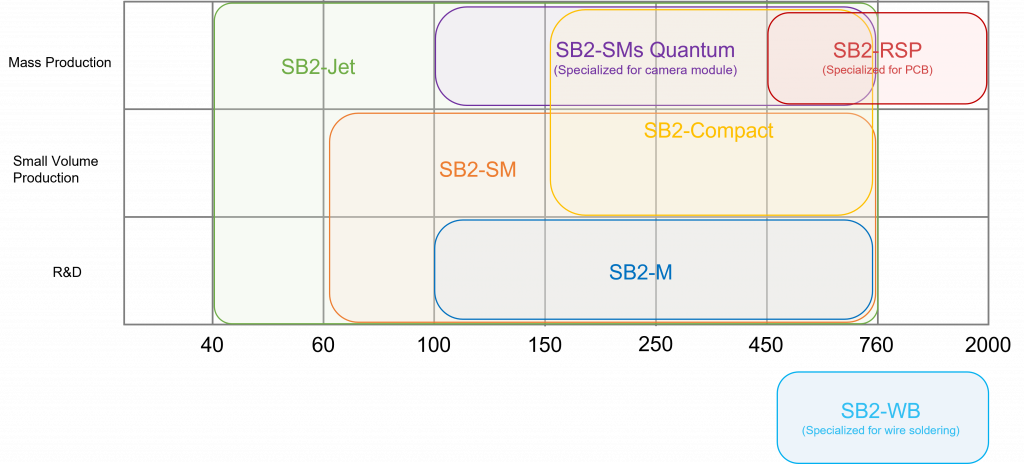

Being a lower cost version of the SB²-Jet without compromising its placement accuracy, the SB²-SM is a sequential solder ball attach and laser reflow system that can operate either in a fully automatic or in a semiautomatic mode. With larger work area than the SB²-M, yet relatively compact foot print than the SB²-Jet, it is ideal for research & development, prototyping and small volume manufacturing.

Highlights

- Jet mode/Standard mode

- Available solder ball diameter: 60 – 760μm

Suitable for chip/wafer/substrate soldering

- Optional ball rework (de-balling & re-balling) capability

Options

- Solder Ball Rework Station

- Pattern Recognition and Fiducial Alignment

- Upgrade to 8” working area

- Heated chuck/work stage

- Specific heated work holder for BGA-like devices

- Automatic Z-height measurement

Benefits

- High flexibility

- Small solder ball handleability

- Rework function

SB² – SM Products & Applications

Products

- Wafer Ø up to 8″

- Substrates

- Single Chips

- MEMS & 3D Package

- Hard Disk Drive (HDD)

- CMOS Sensors

- Opto-Electronics

- Microoptics

Filter Devices

(SAW, BAW, F-BAR)

Applications

- Prototype Build

- Repair/Rework

- Single Chip

- Wafer Level Chip Scale Packaging (WLCSP)

- Flip Chip

- Ball Grid Array (BGA)

- Printed Circuit Board (PCB)