LASER SOLDERING MACHINE – SB²

Our laser solder jetting technology is clean, precise, and flexible. Our unique ball handling mechanism supplies a separated single solder ball into the capillary where the laser beam’s thermal energy melts the solder ball, and the solder is deposited to arbitrary positions and being reflowed immediately. It works with various solder alloys of different melting point and requires no flux therefore it is clean.

The localized heat and short pulse are generated by the laser that assures minimal thermal stress is applied on the area beyond the joined surfaces. The selective single solder ball dispensing mechanism requires no tooling for masking soldering locations, hence enables flexible soldering location and contactless soldering.

Highlights

- Fluxless

- Mask/Stencil-less

- Clean

- Precision

- Low Thermal Stress

- 3D Soldering

Laser Soldering Process

Choose the bonding mode that best suits your application.

Jet Mode

- Higher throughput

- 3D Soldering is possible

- Can handle smaller balls

Standard Mode

- Better energy efficiency

- For process with flux / For heavily oxidized pads

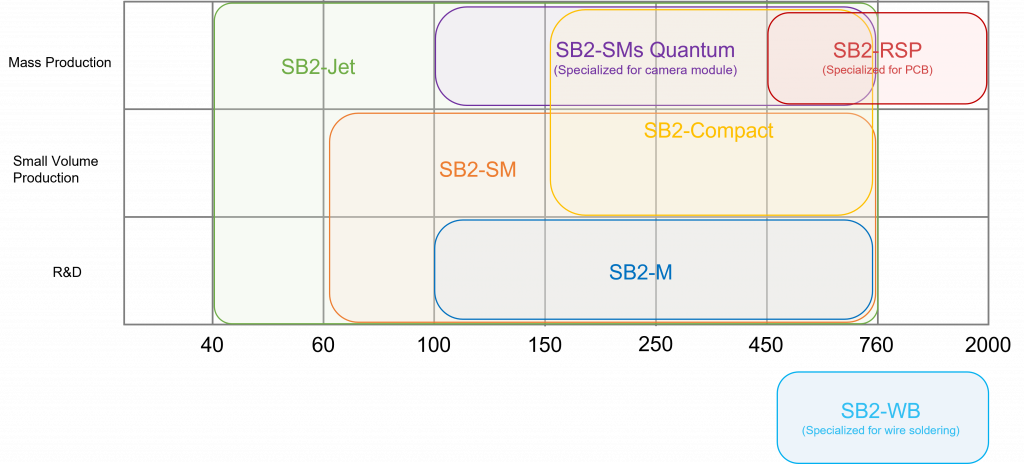

SB² – Product Chart

SB² – Equipment

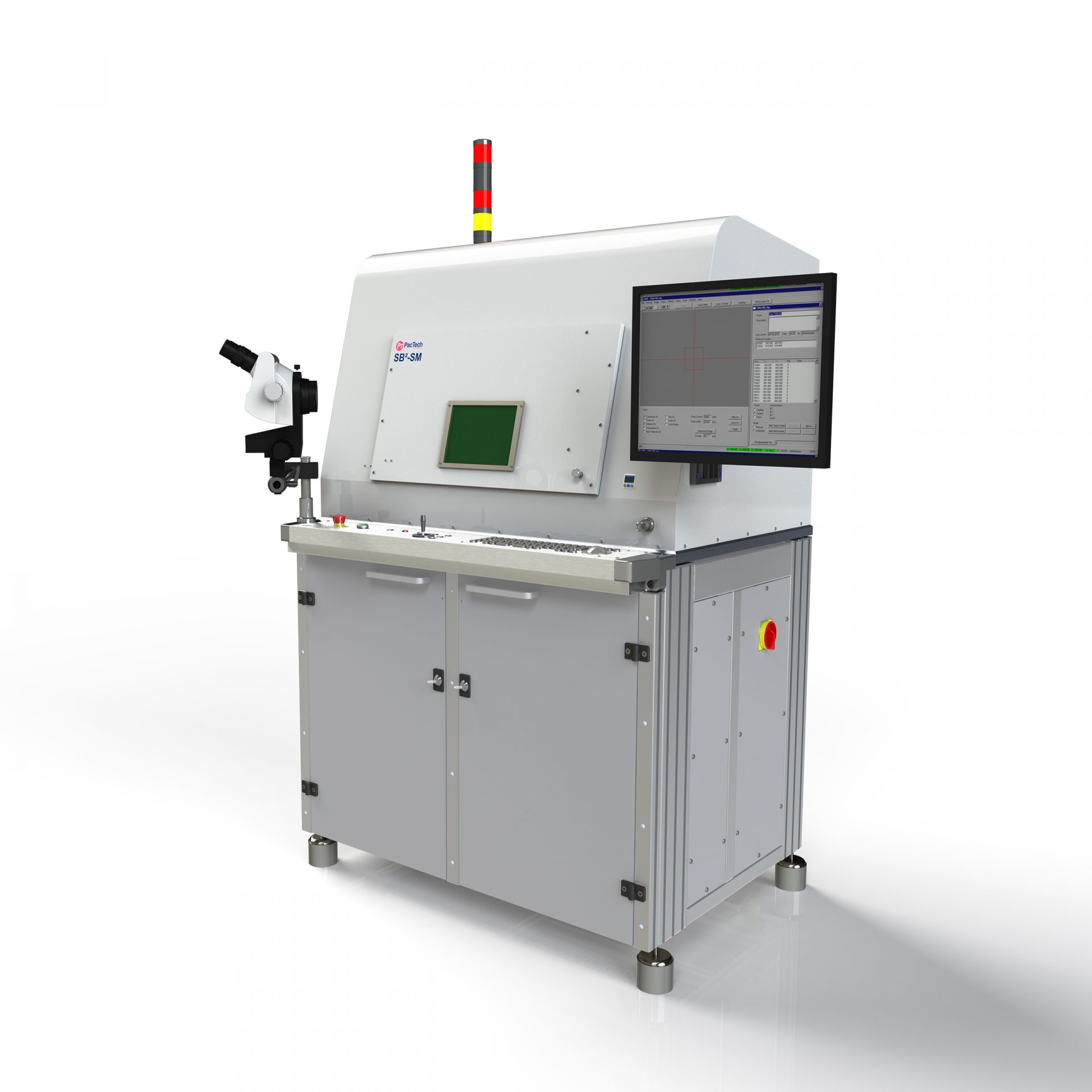

SB² – SM

The SB2-SM is a machine for prototyping and small volume production that has wider working area than the SB2-M and more optional features.

SB² – Compact

SB²-Compact machine is the SB² entry point for high volume production with highly flexible and ultra-compact workstation.

SB² – USP

Highly flexible laser soldering and assembly platform for SMT components, especially for high-volume production in the automotive industry.

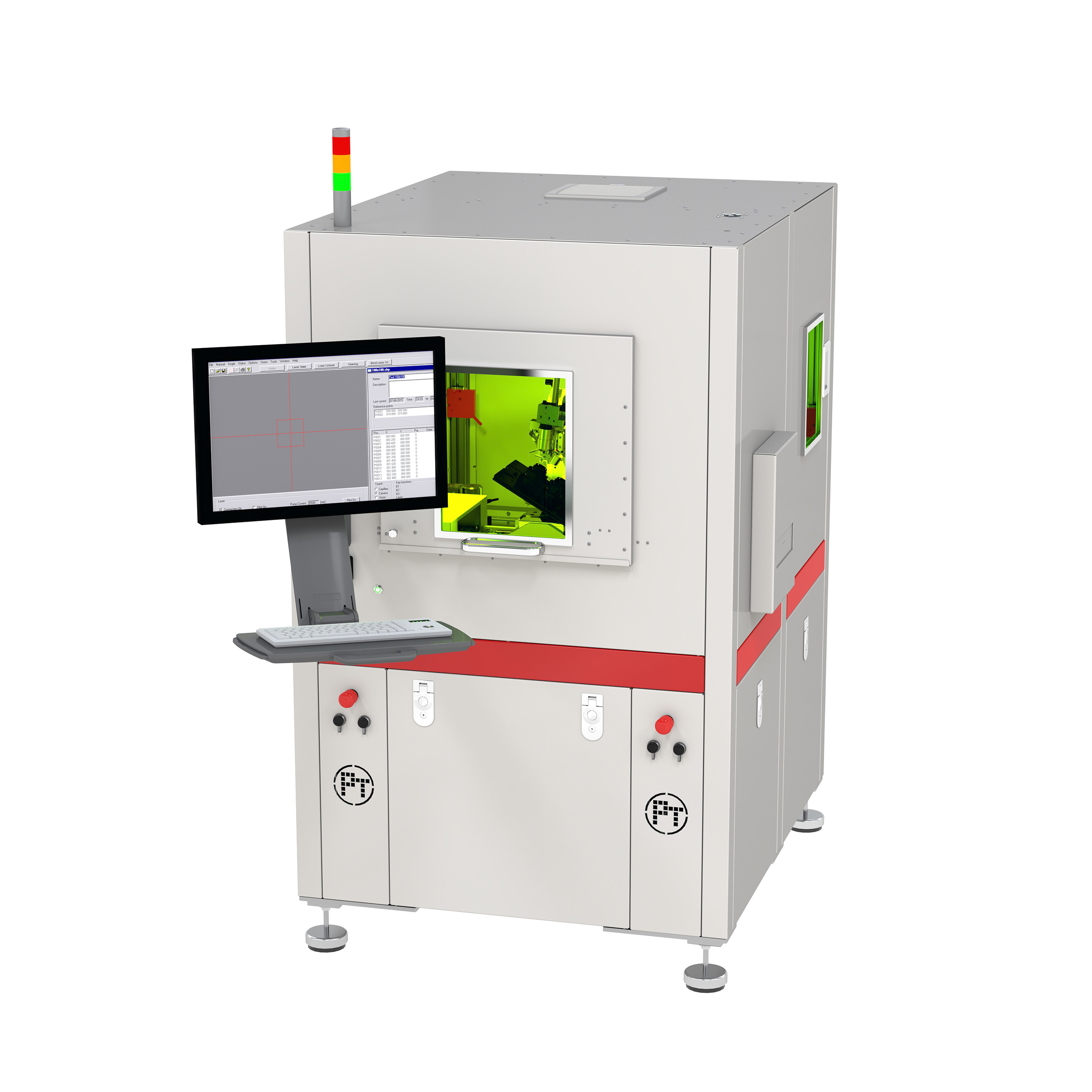

SB² – Jet

SB²-Jet is the machine with the highest placement precision and smallest solder ball capability.

SB² – WB

SB²-WB is a combination of PacTech’s unique solder ball jetting machines with a wire feeding mechanism to perform wiring process.

SB² – SMs Quantum

SB²-SMs Quantum is highly recommended solution for high volume production. It achieves high throughput with dual loading station/drawer system that realize continuous production.